Positioning Tables

Video:

The advantages of our Positioning Tables

Precise, compact guide units

No backlash

Radial play of the guideways

< 0.02 mm

Preloaded self-locking spindle nut and spindle bearing

High quality

Materials

Bearing bracket, carriage and rotary knob made of aluminium, machined and anodised on all sides

Guides hardened and ground, stainless steel

Stainless steel spindle

Brass sliding bushes

Customised variants

Scale knob, mechanical or electronic position indicator

Customised special lengths

4 sizes:

04 / 08 / 12 / 25

Combinations / Variants

-

short positioning table PT1104Learn More

short positioning table PT1104Learn More

- Spindle pitch 0.5 mm

- 1 graduation mark corresponds to 0.05 mm adjustment travel

-

long positioning table PT2304Learn More

long positioning table PT2304Learn More

- Spindle pitch 0.5 mm

- 1 graduation mark corresponds to 0.05 mm adjustment travel

-

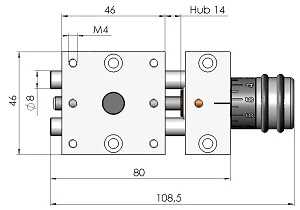

Short Positioning Table PT1408Learn More

Short Positioning Table PT1408Learn More

- Spindle Pitch 1 mm

- 3 different types of position display:

- Adjustable scale knob

- Mechanical position indicator

- Electronic position indicator

-

Long Positioning Table PT4808Learn More

Long Positioning Table PT4808Learn More

- Spindle pitch 1 mm

- 3 different types of position display:

- Adjustable scale knob

- Mechanical position indicator

- Electronic position indicator

-

Short Positioning Table PT2512Learn More

Short Positioning Table PT2512Learn More

- Spindle pitch 1 mm

- 3 different types of position display:

- Adjustable scale knob

- Mechanical position indicator

- Electronic position indicator

-

Long Positioning Table PT7312Learn More

Long Positioning Table PT7312Learn More

- Spindle pitch 1 mm

- 3 different types of position display:

- Adjustable scale knob

- Mechanical position indicator

- Electronic position indicator

-

Long Positioning Table PT8625Learn More

Long Positioning Table PT8625Learn More

- Spindle pitch 2 mm

- 3 different types of position display:

- Adjustable scale knob

- Mechanical position indicator

- Electronic position indicator

Manual positioning table with slide guide directly from the positioning table manufacturer

A manual positioning table enables the precise, linear displacement of stops, switches, sensors, cameras and other devices, assemblies or components.

This makes it particularly suitable for use in special machines, test benches, laboratory equipment and in general mechanical engineering. As a linear unit manufacturer, we offer axial play-free, manual positioning tables with a self-locking spindle in two designs.

The short version is available in three sizes, the long version in four sizes. Our short positioning tables have a one-sided support that supports space-saving installation and offer a stroke range of between 11 and 25 millimeters. With the long forms, the linear slide guide is supported on both sides, so that we can realize strokes between 23 and 86 mm with a slim linear unit.

All of our manual positioning tables are designed as a modular system and can be supplied in various configurations.

Linear adjuster with scale button, optionally readable on the position indicator

We deliver our manual positioning table in three configurations.

The adjustment is precise, either via a simple scale knob with graduations or a rotary knob with a mechanical or electronic position indicator.

All parts of our carriage guide with spindle are made of high-quality materials. We manufacture the bearing blocks and carriages from anodised aluminium, the guide columns and spindles from stainless steel and the maintenance-free plain bearings for the carriage guide from brass.

Further equipment details of the manual positioning tables: As a manufacturer of slide guides, we manufacture with absolute precision. The radial play of the linear unit is less than 0.02 millimeters. The self-locking spindle makes it unnecessary to lock the carriage guide after adjusting the position. An optional clamping screw protects against unintentional adjustment of the linear unit. Our modular system offers a wide range of options for installing the payload and the positioning tables themselves. These can be flexibly combined with each other and with other accessories from our range.

Linear positioning table can be combined in the positioning system

The excellent compatibility with each other and with accessories such as connection modules and rotary elements from our program opens up a wide range of applications for a manual positioning table from our program. Multi-axis positioning systems can be implemented by connecting several tables. The mounting bracket allows system parts to be arranged at an angle of 90° or 45°. Our turntables allow precise pivoting around an axis that is perpendicular to the mounting surface and reliable determination of the set position. Our mounting plates for positioning tables, also made of anodized aluminum, create additional flexibility when setting up a positioning system.

Our Positioning Tables are also available motorized.