Motor Positioning Tables

Positioning table electric

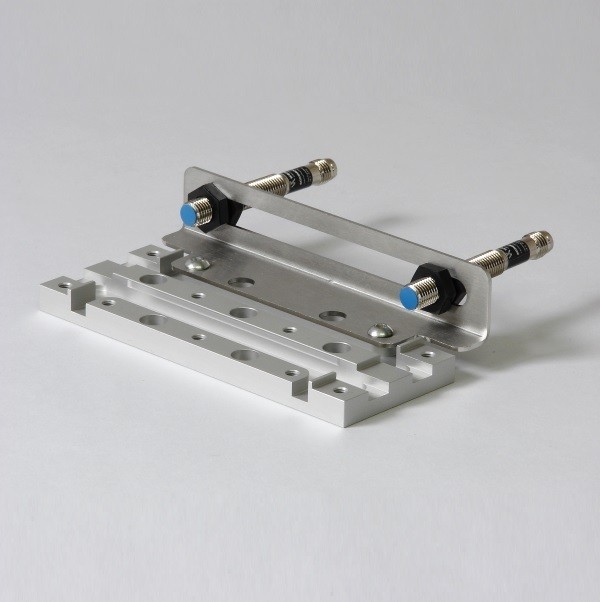

Our motor positioning stages offer a robust, reliable and cost-effective solution for automated, linear positioning. We offer the motorized linear table in two designs, short and long, each in two sizes. The short design is a space-saving solution for a stepper motor linear drive. The slide guide is only mounted on one side here. The slide on the linear table with drive moves like on a cantilever. With the long motor positioning table design, on the other hand, the guide rods are mounted on both sides, so that a stiff, slim construction is possible.

The travel is 24 or 30 millimeters for the short tables and 50 or 75 millimeters for the long tables. The diameter of the guides 8 and 12 millimeters.

Linear table electric / stepper motor linear drive with drive variants

As a further option in addition to the various sizes and designs, we offer our linear actuator in two drive variants, with coaxial or lateral drive. In this way, the available space can be optimally used when installing the motorized positioning elements. For the same reason, the cable outputs on the linear actuator can also be assembled. The space required in the axial direction can be significantly reduced by flanging the motor on to the side. This is particularly interesting with the long design of the motorized linear table, which is longer than the short one due to the double bearing.

Motorized linear drives

Equipment options for the linear actuator

For flexible use in new designs and for retrofitting, we supply our motor positioning table in three versions with regard to the drive equipment. Firstly as a complete solution with a compact drive and controller. Secondly only with a suitable stepper motor and thirdly without a motor at all.

The linear actuator is designed for a stepper motor according to the Nema 17 standard. We use a Gunda GSM 17 as the motor with controller for the linear drive stepper motor, which enables reference travel without a proximity switch. The motorized linear table allows a maximum speed of 600 rpm. Thanks to our modular system, the electrical positioning table can be combined with another stepper motor, linear drive and numerous other components. This also includes rotary modules, manual positioning elements and mounting plates