Swivel Mounts

Aluminium ball clamps

Can be swivelled by ±30°

Rotates 360°

Can be clamped using a clamping screw or without tools using a clamping lever

Versatile mounting options

Easily removable threaded nuts to use a DIN 912 screw instead.

The swivel mounts can be easily connected to the other positioning elements from MM Engineering.

Video "Application example of the GK25 swivel mount"

-

Swivel Mount GK04Learn More

Swivel Mount GK04Learn More

- swivels by ± 30

- rotatable by 360

-

Swivel Mount GK08Learn More

Swivel Mount GK08Learn More

- swivels by ± 30

- rotatable by 360

-

Swivel Mount GK12Learn More

Swivel Mount GK12Learn More

- swivels by ± 30

- rotatable by 360

-

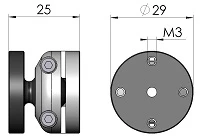

Swivel Mount GK25Learn More

Swivel Mount GK25Learn More

- swivels by ± 30

- rotatable by 360

Clampable ball joint: - free, fixable tilting and rotating connection

Free positioning that is not based on coordinates is the area of application for our rod ends.Equipped with a ball head and clamping screw or clamping lever, the articulated head can be rotated over 360° around an axis that can be tilted by ±30°.

With these properties, our clampable ball joint is suitable for tasks such as positioning cameras, displays, laser projectors, sensors, lighting spots and much more.

Ball head clampable: Fasten components in an articulated, rotatable and tiltable manner

Our ball clamps can also be used to variably support free-form workpieces for clamping or fastening.We supply rod ends in four different sizes from stock, starting with the GK04 rod end with a diameter of 29 millimeters, up to the GK25 with a diameter of 150 millimeters.

Clampable articulated head: rotation and tilt adjustment for sensors and other objects

Our lockable ball joint can be reliably connected to devices, sensors, other positioning elements and other components via four bores each equipped with press-out nuts on the base and on the plate, which is articulated by means of a rotary joint.

This results in numerous possible uses. Components mounted on the spherical bearing can be rotated freely after loosening the clamping screw and tilted up to 30° in any direction. This largely free mobility enables easy positioning, for example on machine tools or a positioning system.

Finally, tightening the clamping screw fixes the slewing ring in the set position. With the smallest ball joint head, model GK04, the clamp absorbs torques of up to 3 Nm, with the largest it is 150 Nm. This means that our rod end range covers a wide range of loads in the application.

Combine ball joint with clamping in the positioning system with rotary modules, linear units and connecting elements

With their mounting elements, our rod ends also fit into our modular system for positioning. They can therefore be flexibly combined, even to form complex positioning systems. For example, the ball joint head in connection with a turntable allows precise positioning with respect to a rotary axis and at the same time angular positioning in all other directions.

Another typical application example is the positioning of cameras and sensors so that their viewing angle covers a given object field. In general, the lockable ball joint is suitable for the free adjustment of elements that are attached to fixed supports, linear units or rotary modules. To do this, they can not only be connected directly to our positioning elements.

The connection modules from our program facilitate the angled or offset assembly of rod ends and other elements from our modular system.