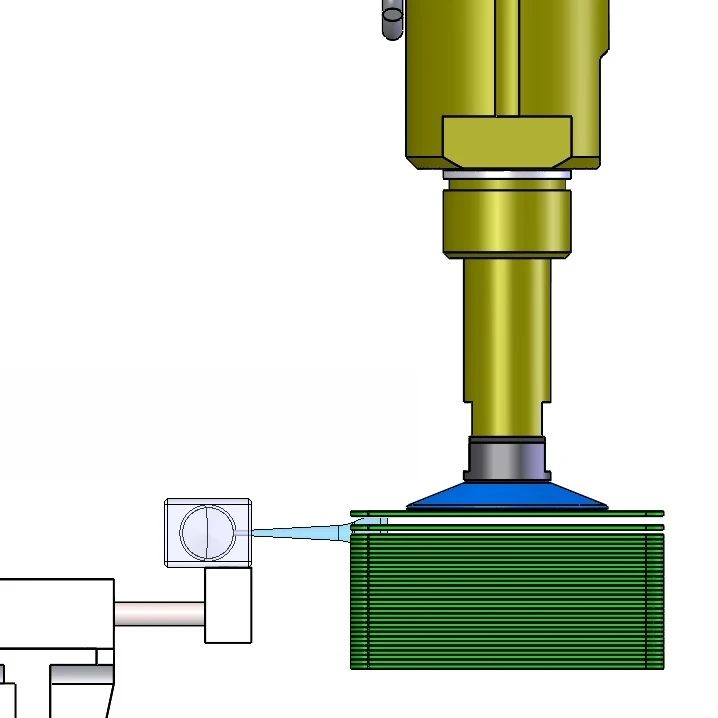

Suction Lifters

Sensitive picking of parts only by switching on vacuum

The vacuum lifters from MME offer many advantages thanks to their unique function.

The cylinder is only connected to one vacuum line

The piston extends when the vacuum is switched on.

As soon as the suction lip on the suction cup touches and seals the workpiece, it is sucked in and the piston in the lifting cylinder moves back to the starting point.

The suctioned part is held in position until the vacuum is switched off.

The advantages at a glance:

- The movement of the vacuum lifter is only controlled by switching on the vacuum

- Gentle contact of the suction cup on the workpiece thanks to lightning-fast reversal of direction

- Stacked or pre-separated parts are not pressed together

- Different workpiece heights are automatically equalised.

- Extremely short cycle times and fast positioning possible due to low weight

- Cost-effective solution by saving on software and hardware

- Simple energy supply, operation with just one vacuum line and one 3/2-way valve

- Numerous mounting options

Versatile areas of application

MM Engineering vacuum cups can also be used, for example, as suction pads for robots in the automotive or plastics industry.

Other applications as vacuum lifters for cardboard boxes or sheet metal, wood and veneers are also possible.

Position query optional

As an option, our vacuum lifters offer the option of monitoring the retracted end position using a magnetic field sensor to ensure a safe handling process.

Magnetic field sensor occupied + vacuum on = workpiece gripped and lifted

Vacuum grippers, fast and sensitive

Many variants for different applications

Our lifting cylinders are faster than a frog at catching flies

Our fastest suction lifter, for example, needs less than 60 msec. to pick a component from a distance of 15 mm. (extend, grip, retract)

The right size for every application

Vacuum suction pads are available in 7 sizes for lifting workpieces of different shapes and weights simply by switching on a vacuum.

The suction pads have a stroke of 17 mm to 80 mm and a lifting force of 3N to 50N.

For separating stacked workpieces

The vacuum suction cups are used wherever flat workpieces such as plastic cards, veneers or signs need to be separated quickly.

For example, the vacuum lifting cylinders are used for the safe separation and feeding of stacked workpieces in sheet feeders and magazines in the printing industry, paper industry or plastics industry.

Handling of differently shaped parts of all sizes

Other vacuum handling or pick & place tasks can also be performed by our clever vacuum grippers.

The automatic workpiece height-independent direction reversal of the lifting cylinders enables items of different sizes to be lifted.

Processing an ever lower workpiece stack without tracking it is also an advantage of distance-independent gripping.