Timing belt conveyor ZF1825-30 - Compact drive 24V BLDC - Angular gearbox

Make an inquiry!

We manufacture your timing belt conveyor according to your requirements.

Call

+49 8093 90143 70

Compact, powerful timing belt conveyor

Belt coatings for every application

You can choose between numerous properties and coatings for the quality of the timing belt.

Whether oil-resistant, suitable for foodstuffs or equipped with various cleats, we will be happy to advise you.

Flat motor with angular gearbox 24V BLDC

Cable assignment

with external speed control

0-5 V

(7-core cable, length 5 m)

- white: +24 V power supply reverse polarity protected

- brown: Gnd power supply reverse polarity protected

- green: Digital input 1 (max 30V; on >9V; off <3.7V)

- yellow: Digital input 2

- grey: 0 - 5 V analogue speed control from 12 % to 100 % of the nominal speed (optional)

- pink: Signal Gnd (for speed control)

- blue: Reserve

Cable assignment

with potentiometer

(4-wire cable, length 5 m)

- white: +24 V power supply reverse polarity protected

- brown: Gnd power supply reverse polarity protected

- Green: Digital input 1 (max 30V; on >9V; off <3.7V)

- Yellow: Digital input 2

Description of the digital inputs

| Input 1 | Input 2 | Condition |

| 0 | 0 | Switched off |

| 1 | 0 | Direction 1 |

| 0 | 1 | Direction 2 |

| 1 | 1 | Stop (brake) |

Easy to integrate thanks to system profile

Structure

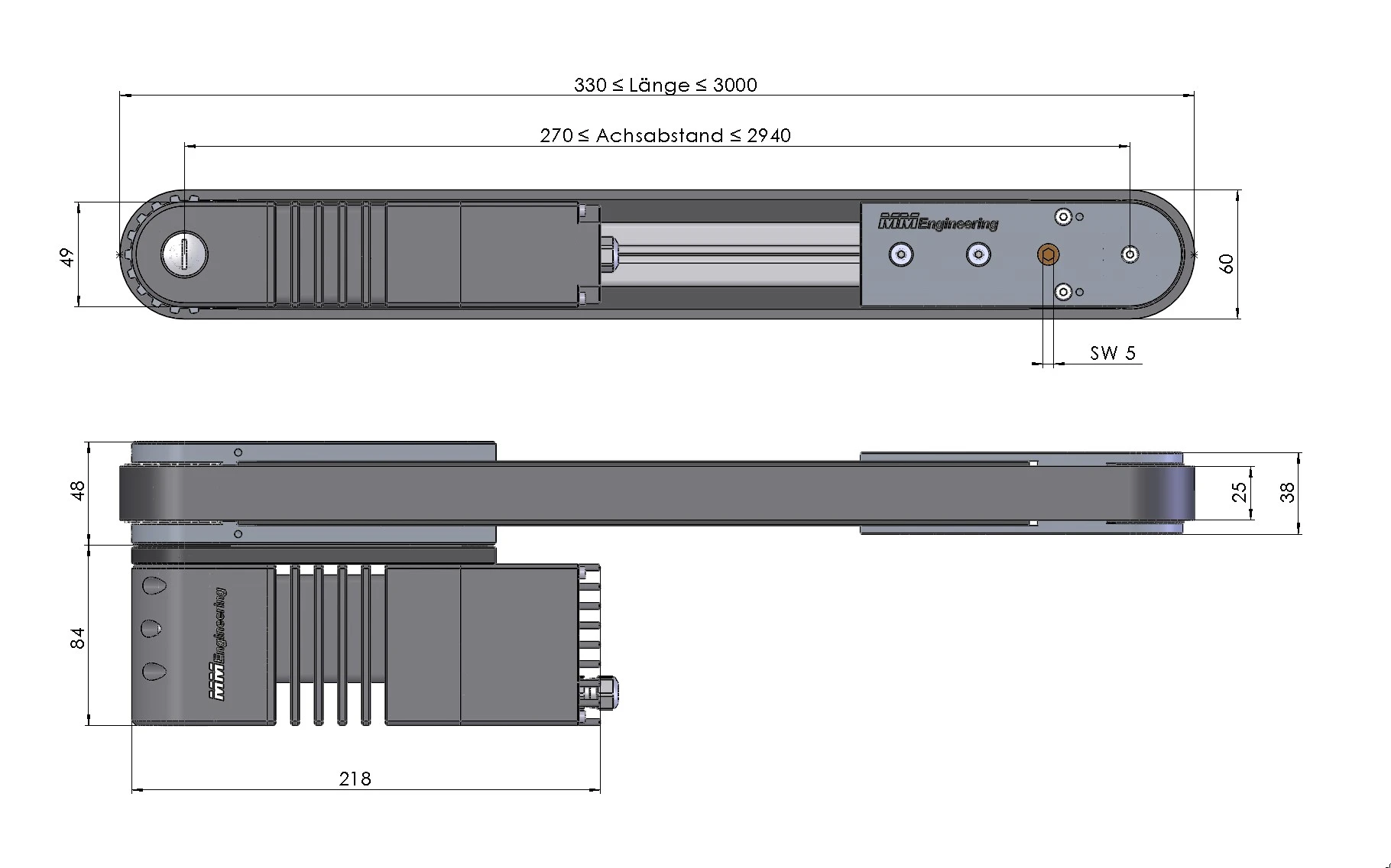

- Base frame made from Bosch 30 x 30 mm strut profile system

- PE belt guides

- Toothed belt pulley with 18 teeth

- Effective diameter ~ Ø57.3 mm

- Anodised aluminium bearing plates

Mounting options

- on the Bosch profile frame with grooves

- on the threaded holes in the bearing brackets

- on customised mounting points

- customised racks

| speed | conveying speed | max. load |

| 105 rpm | 18 m/min | 15 kg |

| 240 rpm | 40 m/min | 6 kg |

Feed rate adjustable from 12 % to 100 % via 0-5 V analog signal.

Operating voltage: 24 V DC

Max. current: 9 A

The right conveyor belt for every application

- authorised for foodstuffs

- heat resistant

- oil resistant

- transparent for transmitted light

- Antistatic finish

- eligible for congestion

- with different surface structures

- with welded profiles

Order example

ZF1825-30-200-1200-40-2S-LI

- ZF = Toothed belt conveyor

- 18 = Drive with flat motor 24V BLDC, angular gearbox

- 25 = Belt width 25 mm

- 30 = Support profile 30 x 30 mm

- 200 = Width at the outer edges of the outer conveyor lines

- 1200 = Overall length outside (= centre distance 1140 mm)

- 40 =Belt speed

- 2S =Number of conveyor lines 2

- LI = Motor arrangement left inside