Vertical Lift Stages

Vertical lift stages in flat design

compact design

Backlash <0.05 mm

pre-tensioned self-locking spindle nut and spindle bearing

Stroke movement linear to spindle rotation

Scale button with reset function (from size 8)

By turning the scale ring in relation to the spindle, the lifting plate can be zeroed at any position or any scale value can be set.

Different variations

Scale rings also available with numbers upside down for vertical installation.

4 sizes: 4 / 8 / 12 / 25

Manual flat-form lifting tables with a wide range of applications: from the mini lifting table to the 700 N lifting table

Height-adjustable carriage with manual adjustment for different size ranges

According to the design, a lifting table implements the Z-axis adjustment in a three- or higher-dimensional positioning system, but can also be used for one- or two-axis positioning.

Our precise, flat-form lifting tables with manual adjustment supplement our modular system of manual positioning elements with suitable units that are height-adjustable. With its four sizes, the flat lifting table covers a wide range of positioning tasks that require precise fine adjustment.

The smallest model, the mini lifting table HT04, achieves a force of 50 Newtons with a stroke of four millimeters, corresponding to a weight of around five kilograms. At the other end of our product range of flat form lifting tables is the flat lifting table HT25 with a lifting force of 700 Newtons and a lifting height of 25 millimeters.

Each manual lifting table can be adjusted as standard using a scale knob with 0.025 to 0.05 millimeter divisions, depending on the selected size.

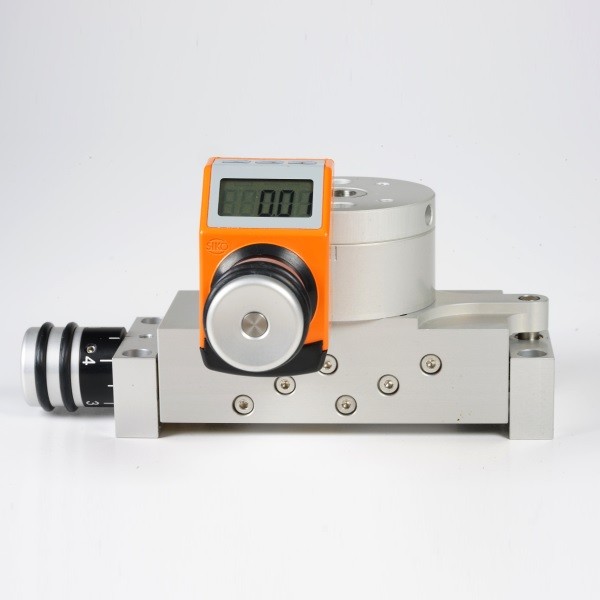

Lifting table and lifting unit for manual positioning with dial knob or position indicator

We supply our flat lift table with manual operation in all sizes either with a scale button or with a position indicator in a mechanical and an electronic version. Depending on the design and size, the setting accuracy is between 0.1 and 0.01 millimeters.

The lifting table spindles are self-locking and therefore do not require clamping. With regard to the other equipment, the lifting tables from our program are also characterized by their high-quality selection of materials. The guide rods and spindles of the precise sliding guide in our lifting table or mini lifting table are made of stainless steel and the bushings of the maintenance-free bearings are made of brass. We precisely mill the bearing blocks and carriages for each flat lifting table from anodized aluminum, which we also use for the scale knobs.

Our sophisticated system of fastening elements offers a wide range of combination options with other positioning modules and other accessories from our range.

Flat lift tables can be combined in many ways in the positioning system

In addition to their excellent mechanical properties, our flat-form lifting tables are characterized by their modular system, in which they can be universally combined to form optimal positioning systems.

Our lifting systems complement each other with versatile positioning elements for linear adjustment and rotary components to form systems that enable precise positioning of components, sensors, workpieces, guides and the like, even under complex framework conditions. For example, a mini-lifting table for the Z-axis, two positioning tables for X and Y and a rotary table become a positioning system that first enables the exact infeed to a specified point in space and then a highly precise rotation around an axis that is defined by this fixed point the flat lifting table.