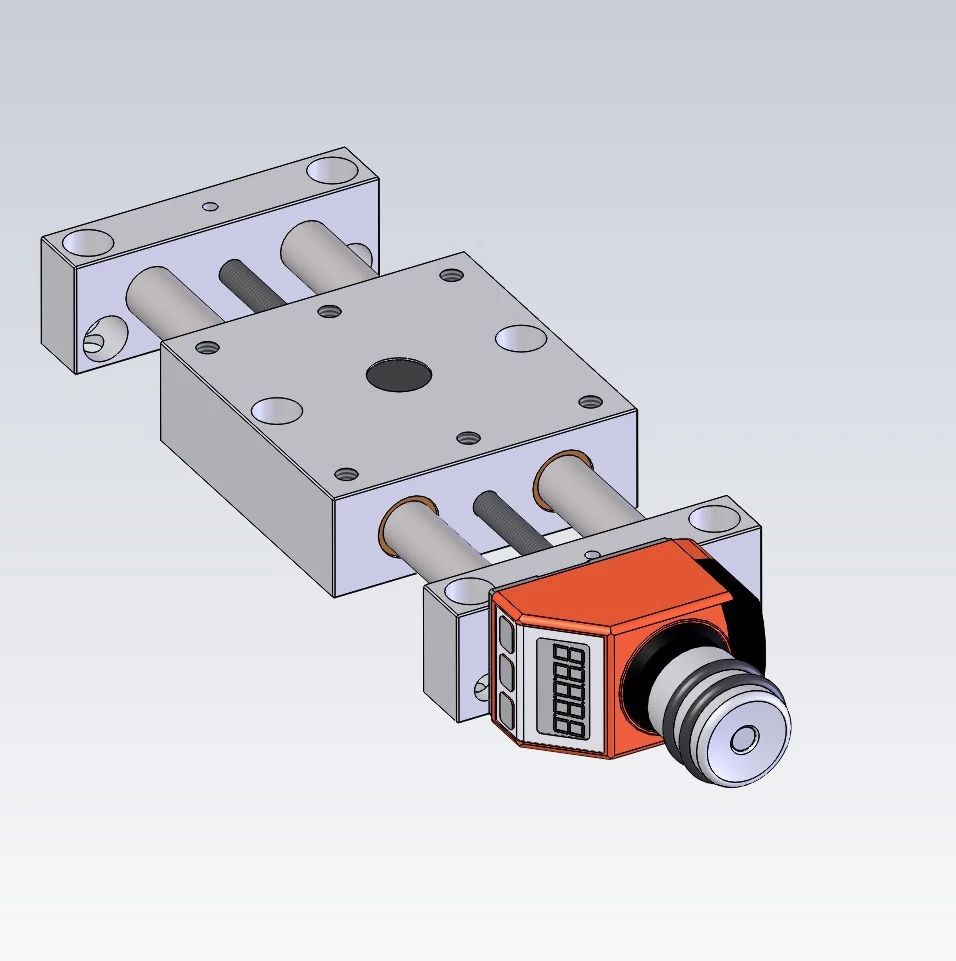

Long Positioning Table PT7312

- from 5 pieces 5%

- from 10 pieces 9%

- from 25 pieces 12%

- Spindle pitch 1 mm

- 3 different types of position display:

- Adjustable scale knob

- Mechanical position indicator

- Electronic position indicator

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

|

CAD (step) PT7312 | zip | 3.6 MB | Download | |

|

Flyer Positioniersystem manuell / Manual Actuators | 2.3 MB | Download | ||

|

Kurzanleitung Positioniersysteme manuell | 2.6 MB | Download |

Function

- The slide of the positioning table can be adjusted linearly by turning the scale knob by hand.

- One graduation mark of the scale knob corresponds to 0.05 mm of adjustment travel.

- The scale ring can be adjusted relative to the spindle.

Due to the preloaded spindle and spindle nut, no clamping is necessary after adjustment. - The spindle can be additionally fixed on the bearing block in the D5 thread with the KS-M4X7 clamping screw.

Advantages

No backlash

Spindle nut and spindle bearing are preloaded. This allows the slide to be positioned from either direction without backlash.

Self-locking spindle

Due to the preload, the control knob offers some resistance when turning. This means that the carriage always holds its position securely.

Modular system

The PT7312 positioning stage can be easily combined with all size 12 adjustment units.

Video "Backlash free positioning with our linear units"

Combination example

Dimensions

Force diagram

Technical data

Precision

Axial clearance: preloaded backlash-free

Radial play of the guide: <0.02 mm

Graduation: 0.05 mm

Dimensions and weight

Travel: 73 mm

Spindle pitch: 1 mm

Mass: 803 g

Operating temperature: -20 °C to +70 °C

Materials

RoHS compliant

Bearing blocks and slides: Anodized aluminum

Guide columns and spindle: stainless steel

Sliding bushes: brass

Position indicator: plastic

Dimensions

PT7312

Dimensions

PT7312-PA

Dimensions

PT7312-PAE

Scale knob

Adjustable scale

To zero in the dial, the scale ring can be rotated and clamped.

Option: Number orientation for vertical spindle position

The scale knob is also available with the digits turned 180° (upside down).

Here the digits are readable with the spindle in vertical position.

Option: Spindle clamping

The optionally available KS-M4X7 clamping screw can be used to additionally secure the spindle against unwanted manipulation.

Mechanical position indicator PA

Mechanical counter

The operator can read the slide position directly on the position indicator with an accuracy of 0.1 mm.

After loosening the clamping screw, the red ring can be rotated to adjust the display indication.

Variable alignment of the position indicator

The position indicator can be rotated 4 x 90° around the spindle axis and fixed. (Picture example "L" left)

Upside down digits (PA/PAE)

The position indicator is also available with 180° rotated (upside down) digits.

Elektronic position indicator PAE

multifunctional position indicator

Reset-, incremental measurement- and offset-button

Large LCD display

Battery life 2 years

Easy battery change without loss of settings

Variable alignment of the position indicator

The position indicator can be rotated 4 x 90° around the spindle axis and fixed. (Picture example "O" over the top)

Hand crank instead of rotary knob (PA/PAE)

For more speedy adjustments, order a handwheel.

Locking lever

Clamping of the carriage on the guide rods

The carriage can be clamped directly to the two guides with two clamping levers.

After pulling the clamping lever axially, it can be disengaged and swivelled into any position. Once released, it engages again by spring pressure.

Order code

PT7312-PA-H-V-HK63

PT = Positioning table

73 = Travel 73 mm

12 = Size 12 (Ø guiding rails)

PA = mechanical position indicator

V = Design of the position indicator: Numbers readable with spindle in vertical position

R = Mounting position of the position indicator: PA points to the right

HK63 = with hand crank 63mm instead of knob