Suction Lifter DHS3025-S

- from 5 pieces 5%

- from 10 pieces 9%

- from 25 pieces 12%

- from 50 pieces 16%

- from 100 pieces 20%

- Lifting force 7 N

- stroke 25 mm

- Piston rod twist-locked

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

|

CAD (step) DHS3025-S | zip | 185 KB | Download | |

|

Katalog Hubsauger / Catalogue Suction Lifters | 10.3 MB | Download | ||

|

Flyer Hubsauger / Suction Lifters | 945.1 KB | Download | ||

|

Montageanleitung DHS | 1.1 MB | Download |

Function

- Switching on the vacuum causes the piston to extend.

- As soon as the suction cup contacts the workpiece, it is sucked in and the piston immediately returns to its starting position with the workpiece gripped.

- The workpiece is held until the vacuum is switched off.

- After the vacuum is switched off, the workpiece is released from the suction cup and the piston remains retracted.

1

Initial position

Vacuum off, piston is retracted.

Optional magnetic field sensor is actuated, LED lights up

2

Switch on vacuum

Piston extends, workpiece is sucked in, piston returns to starting position with sucked-in workpiece.

Optional magnetic field switch is not actuated, LED off

3

Hold vacuum

Workpiece sucked in and lifted off

Optional magnetic field sensor is actuated, LED lights up

Now the transport movement can be started.

4

Switch off vacuum

Workpiece detaches from suction cup.

The release of the workpiece can be supported by the customer with a compressed air pulse.

Piston remains retracted

→ 1. basic position

Advantages

Direction reversal automatically and independent of distance

This allows workpieces of different heights to be gripped easily.

An increasingly low stack of flat workpieces can be processed part by part.

Sensitive gripping without pressure on the workpiece

The automatic reversal of direction of the suction cup is so fast that no pressure is exerted on the workpiece during gripping.

This allows flat components pre-separated by blowing air to be lifted directly from the air cushion.

A fanned-out stack is not compressed again when the uppermost component is lifted off.

Functions only by switching vacuum on and off

Consequently, only one vacuum line and one 3/2-way valve are required.

In many cases, the single vacuum line can also be installed freely without an energy supply chain.

This saves material and installation costs.

Special features

Sensor for sensing the retracted position optional

As an option, a magnetic field sensor can be attached to the lifting suction unit to check the retracted piston position.

At the same time, this monitors the presence of the workpiece. If the workpiece is lost, the piston extends and the sensor signal drops out immediately.

Non-rotating piston rod

The twist-locked piston rod enables position-oriented handling of components.

A slight amount of rotational play is inherent in the design.

Numerous mounting options

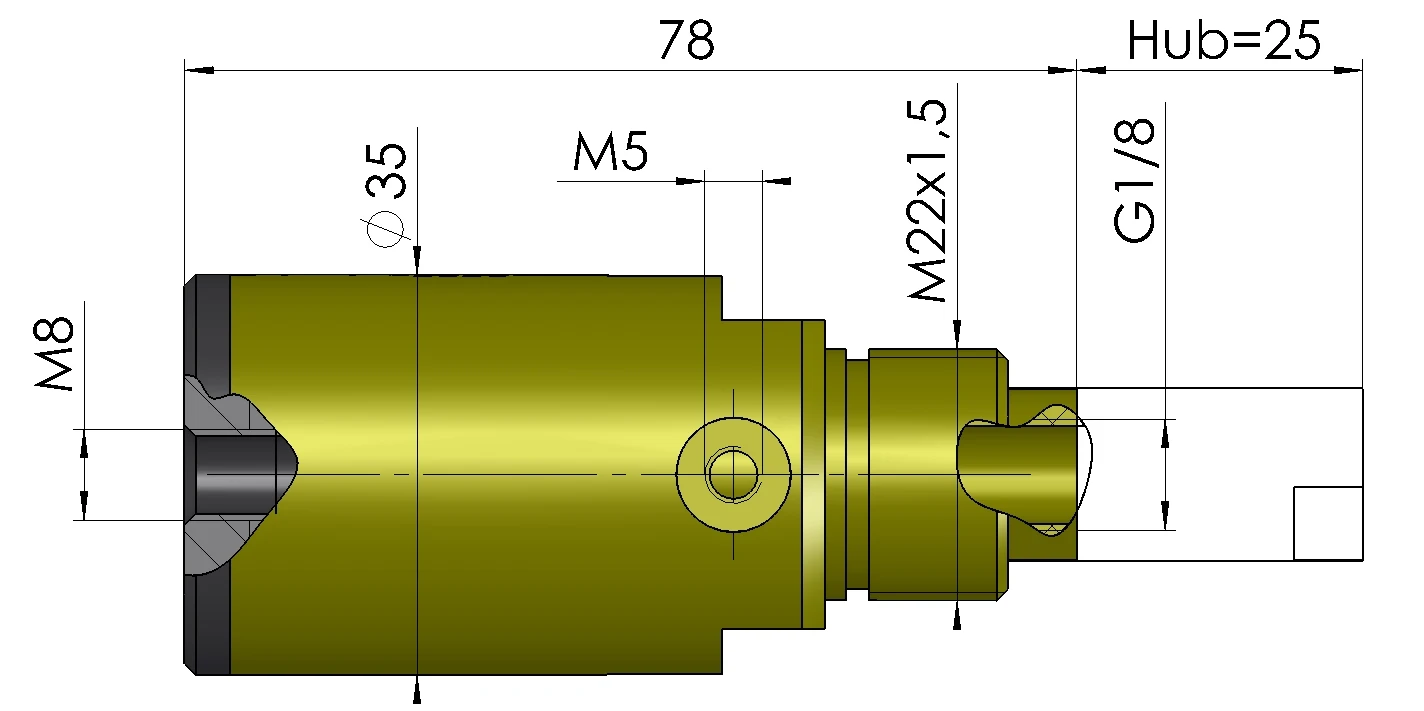

In the cover of the vacuum lifting cylinder there is a threaded hole M8, which is used for mounting the lifting cylinder.

Furthermore, there is a fine thread M22x1.5 on the shaft, which corresponds to that of ISO pneumatic cylinders. This means that the brackets available for this purpose from all manufacturers can be used. The flat nut is included in the scope of delivery.

Video: Function and application of our vacuum grippers (duration 2 min.)

Video: Separating workpieces with a vacuum lifter (duration 38 sec.)

Application: Suction lifter device for separating plastic sheets

The advantages of the suction lifter cup are used here

- The level of the sheet pile is not constant.

- The static sheets are separated by lateral blowing with compressed air.

- The piston of the lifting vacuum extends until the suction lip seals and immediately reverses with the sucked sheet.

- The air cushion between the sheets is not forced out. They remain separated.

- The low weight and the actuation by only one vacuum hose favors a fast transport movement to the machine.

Time - stroke diagram

Dimensions

Technical data

Speed

Time for one lifting operation using the full stroke of 25 mm

Workpiece weight 3 g: 140 ms

Workpiece weight 350 g: 255 ms

Workpiece weight 700 g: 475 ms

When using less stroke, the cycle times are correspondingly shorter.

Performance data

Lifting force: 7 N

Required volume flow: >35 l/min

Required vacuum: >0.6 bar (absolute <0.4 bar)

Recommended venturi nozzle diameter of the vacuum generator: 0.7 mm

Dimensions and weight

Stroke: 25 mm

Diameter piston: 30 mm

Mass: 111 g

Materials

RoHS compliant

Piston and cylinder: Aluminum hard coated

Plain bush Piston rod guide: Special plastic