Motorized rotary table with pneumatic chuck MSP108110-SG

- Pneumatic 3-jaw chuck with reversible clamping jaws

- Low-backlash worm gear

- Very robust pivot bearing

- Different drive variants

- Pneumatic rotary union

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

|

CAD (step) Stepper Motors | zip | 1.9 MB | Download | |

|

CAD (step) MSP108110-SG-ixx-Px-B-N23-K6 | zip | 10.5 MB | Download | |

|

CAD (step) MSP108110-SG-ixx-Px-B-N17-K5 | zip | 10.1 MB | Download | |

|

Betriebsanleitung pneumatisches Spannfutter | 1 MB | Download |

Function

- The pneumatic precision chuck forms a high-precision motorised rotary unit with the motorised rotary table.

- Motors of size NEMA17 or Nema23 can be flange-mounted. We also adapt customised drives

- The three-jaw chuck is operated by compressed air and has reversible clamping jaws.

- It enables concentric clamping both from the outside and vice versa from the inside to the outside.

- The concentricity measured on the clamped workpiece is <0.06 mm.

Advantages

Stable bearing

The turntable is supported by a highly rigid, backlash-free cross roller bearing.

Very high loads and tilting moments can be absorbed.

Multifunctional automatic chuck

The pneumatically operated three-jaw chuck has reversible clamping jaws and offers the option of clamping the workpieces from the outside as well as from the inside.

Precise

The rotary actuator is driven by a preloaded, low-backlash worm gear.

The complete unit offers a concentricity of <0.06 mm on the clamped component.

Besonderes Feature

Optionen

Option: Stepper motor with integrated positioning control

Various positions to be approached as well as acceleration ramps, type of search run, speed or current limitation and other parameters are programmed with the help of a free, simple PC software.

The rotary movement is monitored by an integrated rotary encoder.

Technical data

Precision

Backlash ≤ 0.1°

Axial run-out turntable ≤ 0.02 mm

Rotary disc concentricity ≤ 0.02 mm

Concentricity on the clamped part: ≤ 0.06 mm

Repeat accuracy of clamping jaws: ≤ 0.005 mm

speed

Input speed max.: 600 1/min

Output speed max.: 15 rpm

Max. duty cycle: 100%

Ambient conditions

Operating temperature: +10°C to +50°C

Installation position: any

Dimensions and weight

Gear ratio: 40:1 or 20:1

Mass: 6500 g (without motor)

Efficiency η turntable: 0.33

Clamping range outside: 1 mm - 100 mm

Clamping range inside: 20 mm - 100 mm

Travel jaws: 1.33 mm (2.66 mm in diameter)

Clamping force: 200 N at 6 bar

Compressed air for chucks

Operating pressure: 6 bar

Operating medium: Compressed air, unlubricated, in accordance with ISO 8573-1:2010 [7:4:4]

Pneumatic connections: M5

Materials

RoHS compliant

Housing and turntable: Anodised aluminium

Hollow shaft: Stainless steel

Worm: ground steel

Worm wheel: Bronze

Clutch housing: Anodised aluminium

Clutch: aluminium / plastic

Chuck: stainless steel

Rotating union: stainless steel, aluminium, high-performance plastic

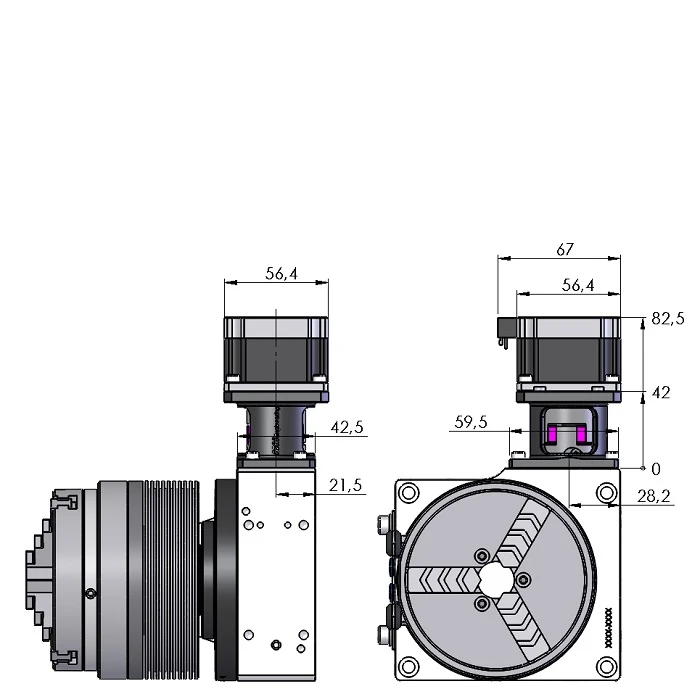

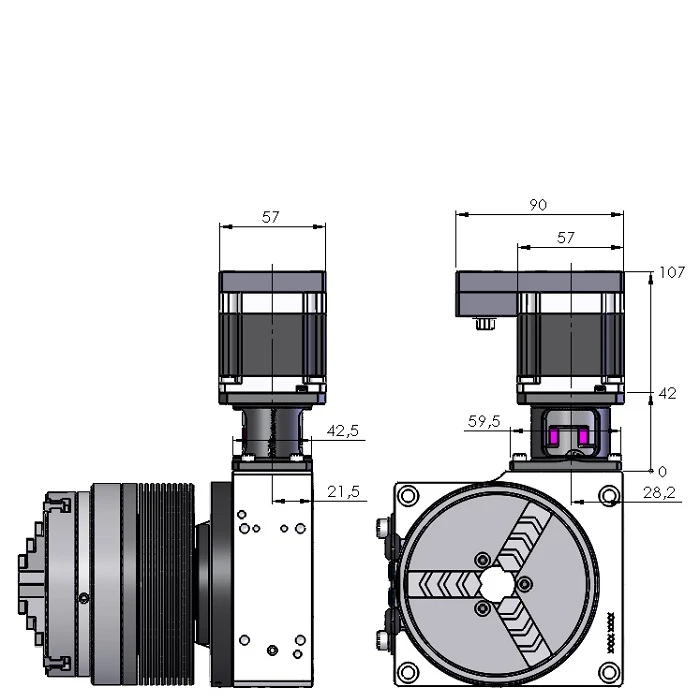

Dimensions without drive

Dimensions drive variants

Motor data

Motor and control data - NEMA 17 with control unit

Control voltage:

Motor voltage:

Connection:

Interface:

Phase current max:

Holding torque:

Current reduction:

Inputs:

Outputs:

Dyn. switching Step resolution:

Encoder:

Protection class:

Werte

+24 V to +36 V DC

+24 V bis +48 V DC

Serial TTL + TTL converter to USB

Sub-D connector 15-pin HD

adjustable up to 3 A

0,43 Nm

adjustable

6 / +24 V to +36 V DC

4 / +24 V DC

1/8 1/4 1/2 1/1

Integrated for position monitoring

IP64

Design - NEMA 17 with control unit

Order code

MSP108110-SG-i40-P3-AK-B-N17-K6,35

MSP = Motorised rotary table with pneumatic chuck

108 = Diameter of the chuck = 108 mm

110 = Diameter of the turntable = 110 mm

SG = Strong Line

i40 = Reduction ratio i = 40 : 1

P3 = Pneumatic connection arrangement Position 3

AK = Drive arrangement coaxial to the screw

B = Basic version without motor

N17 = prepared for motor NEMA 17

K6,35 = Coupling bore for motor shaft 6,35 mm

MPS108110-SG-i20-P1-AK-S-N23L-1

MPS = Motorised rotary table with pneumatic chuck

108 =Diameter of the chuck = 108 mm

110 =Diameter of the turntable = 110 mm

SG = Strong Line

i20 =Reduction reduction i = 20 : 1

P1 =Pneumatic connection arrangement Position 1

AK = Drive arrangement coaxial to the screw

S = with motor and positioning control

N23 =Motor size NEMA23

L = Stepper motor long version

1 =Control orientation Position 1