Short Motor Positioning Table MPT3012

- from 5 pieces 5%

- from 10 pieces 9%

- Stroke 30 mm

- Spindle pitch 2mm

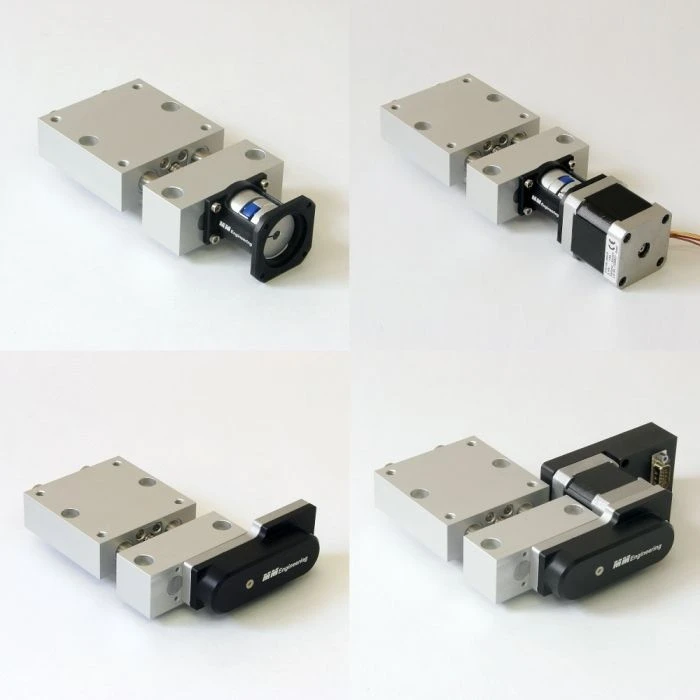

- Available with stepper Motor and controller (Nema 17, □42mm)

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

|

CAD (step) MPT3012 | zip | 12.6 MB | Download | |

|

Flyer Positioniersystem motorisiert / Motorized Actuators | 2.9 MB | Download | ||

|

Montageanleitung MPT V001 | 2.3 MB | Download | ||

|

Programmiersoftware (exe) für Positioniersteuerung | zip | 7 MB | Download |

Function

- The carriage of the motor positioning table is moved linearly by means of a motor and a spindle.

- A standard stepper motor (Nema17, □42mm) can be directly flanged axially or laterally with a toothed belt drive inbetween.

- A stepper motor with an integrated controller is available.

- The spindle pitch is 2mm and the max. input speed is 600 rpm.

Advantages

Cost effective and robust

This motor positioning table offers a cost effective solution for adjustment and positioning tasks in machines and fixtures.

The high-precision long-life sliding guides are vibration-damping and insensitive to shocks and environmental influences.

Low maintenance

The sliding bushes and spindle nuts are suitable for dry running.

For high loads, we recommend lubrication with special plastic grease (Klüber POLYLUB GLY 501).

Modular system

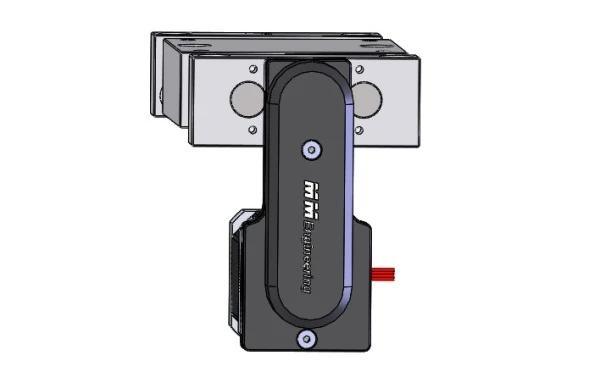

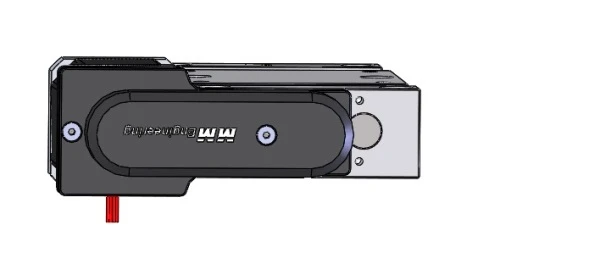

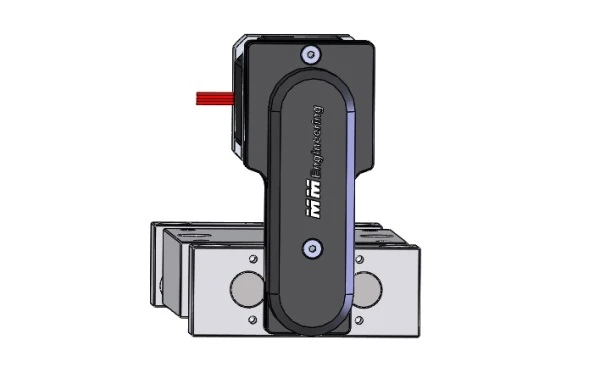

The MPT3012-AK-B motor positioning table can be easily combined with both the motorized and manually operated size 12 adjustment units.

Special feature

Flange with claw coupling

The motor flange is suitable for direct mounting of a NEMA 17 size stepper motor.

The torsionally stiff claw coupling provides vibration-damping torque transmission.

Toothed belt drive variable mountable

The lateral toothed belt drive allows direct mounting of a NEMA 17 size stepper motor.

The toothed belt drive with a ratio of 1:1 can be mounted in 4 positions 4x90°. This allows the linear unit to be configured individually according to the space available.

Stepper motor

The stepper motor offers a resolution of 1.8° / step and a holding torque of 50 Ncm.

The spindle drive is suitable for speeds up to 600 1 / min.

Stepper motor with integrated positioning control

The stepper motor offers a holding torque of 43 Ncm.

The control unit, which is permanently connected to the motor, has an encoder, a control with program memory and a power output stage.

The spindle drive is suitable for speeds up to 600 1 / min.

Technical data

Fx: 60 N

Fy: 100 N

Fz: 60 N

Mx: 0,8 Nm

My: 0,8 Nm

Mz: 3 Nm

Precision

Axial play: <0.04 mm

Radial play of the guide: <0.02 mm

Spindle pitch error: ≤ 0.1 mm / 300 mm

Speed

Input speed max.: 600 1/min

Travel speed max.: 20 mm/s

Duty cycle max.: 100%

Dimensions

Stroke: 30 mm

Spindle pitch: 2 mm

Operating temperature: 10°C to 60°C

Materials

RoHS compliant

Bearing block and slide: Anodized aluminum

Guide columns and spindle: Stainless steel, hardened

Sliding bushes and spindle nut: special plastic

Coupling housing: POM plastic

Coupling: aluminum / plastic

GSM17 Motor / control data

Control voltage:

Motor voltage:

Connection:

Interface:

Phase current max:

Holding torque:

Current reduction:

Inputs:

Outputs:

Dyn. switching Step resolution:

Encoder:

Protection class:

Values

+24 V to +36 V DC

+24 V to +48 V DC

Sub-D connector 15pin HD

Serial TTL + TTL converter to USB

adjustable up to 3 A

0,43 Nm

adjustable

6 / +24 V to +36 V DC

4 / +24 V DC

1/8 1/4 1/2 1/1

integrated for position monitoring

IP64

Design NEMA 17 with controller

Dimensions and Weight