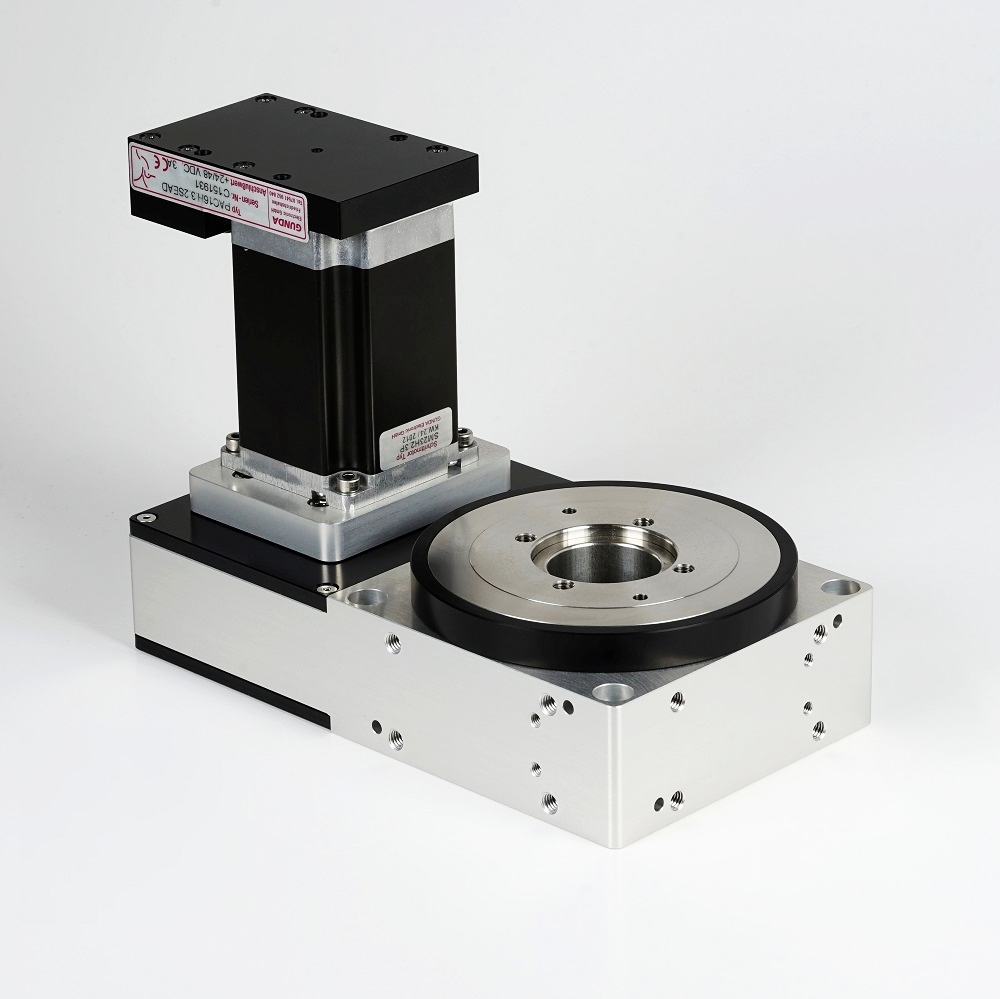

Motor rotary table tooth belt drive with motor and controller MDT360110-QN-MO-S

- from 5 for €1,616.90 each

- from 10 for €1,548.82 each

- from 25 for €1,497.76 each

- Transmission ratio 2 : 1

- with stepper motor and integrated positioning control

- Motor points upwards

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| Katalog Motordrehtische / Catalogue Motor Rotary Tables | 29.9 MB | Download | ||

| CAD (step) MDT360110-QN-MO-S | zip | 2.7 MB | Download | |

| Programmiersoftware (exe) für Positioniersteuerung | zip | 7 MB | Download |

Function

Advantages

Fast and dynamic

The precision toothed belt rotary axis is perfectly suited for positioning components precisely and quickly.

Easy to integrate

Due to the angular design and the versatile mounting options, the rotary axis can be easily integrated into the machine design.

Useful accessories available

Practical matching additional components such as chucks or reference switches with holders round off our range.

Special features

Stepper motor with integrated positioning control

The stepper motor offers a holding torque of 1.75 Nm.

The control unit, which is permanently connected to the motor, has an encoder, a control with program memory and a power output stage.

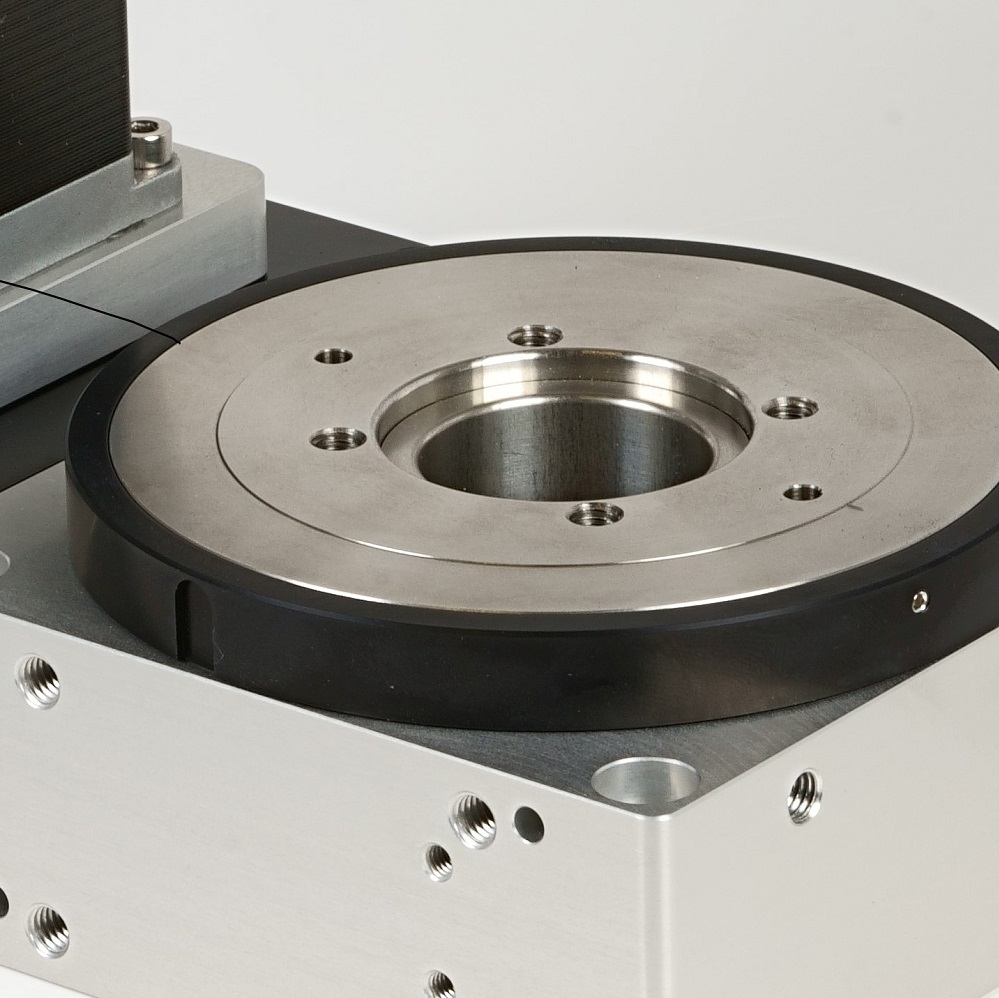

Large passage

The large bore in the hollow shaft with 41 mm diameter allows the passage of pneumatic and electric cables.

It is manufactured to fit H7 and is therefore also suitable for centering the component to be rotated.

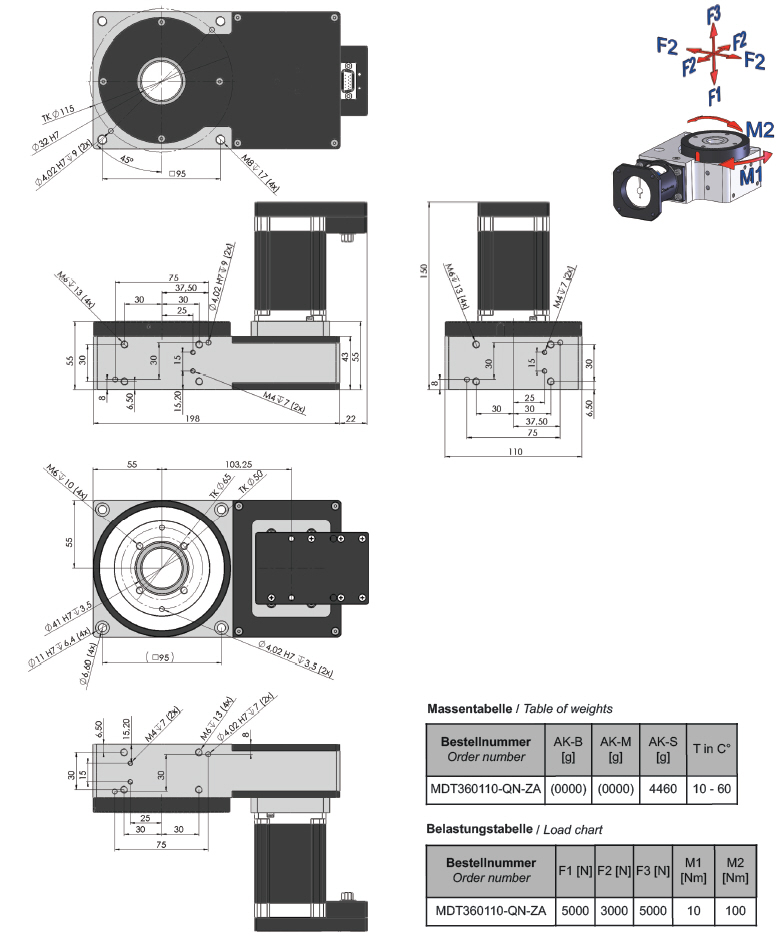

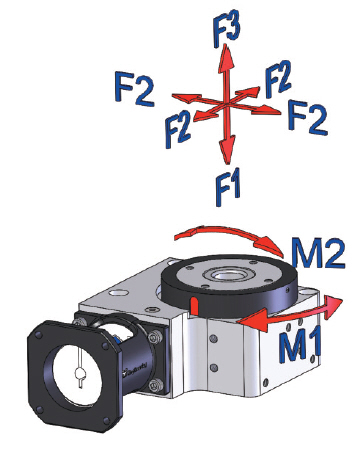

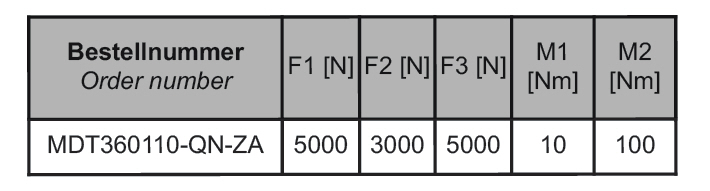

Technical data

Precision

Backlash: <0.2

Concentricity of the rotary stage: <0.02 mm

Axial runout of the rotary stage: <0.02 mm

Speed

Input speed max.: 600 rpm

Output speed max.: 300 rpm

Duty cycle max.: 100%

Efficiency η: 0.85

Dimensions and weight

Gear ratio: 2 : 1

Mass: 4460 g

Operating temperature: 0°C to 50°C

Materials

RoHS compliant

Rotary stage and hollow shaft: Stainless steel

Housing: Anodized aluminum

Motor / control data

Control voltage:

Motor voltage:

Connection:

Interface:

Phase current max:

Holding torque:

Current reduction:

Inputs:

Outputs:

Dyn. switching Step resolution:

Encoder:

Protection class:

Werte

+24 V to +36 V DC

+24 V to +48 V DC

Serial TTL + TTL converter to USB

Sub-D connector 15pin HD

adjustable up to 3 A

1,75 Nm

adjustable

6 / +24 V to +36 V DC

2 / +24 V DC

1/8 1/4 1/2 1/1

integrated for position monitoring

IP64

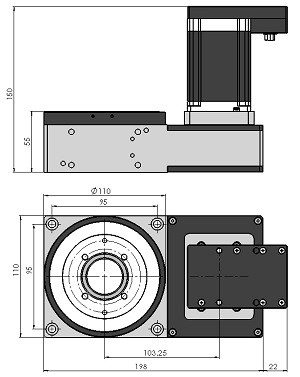

Dimensions

MDT360110-QN-MO-S