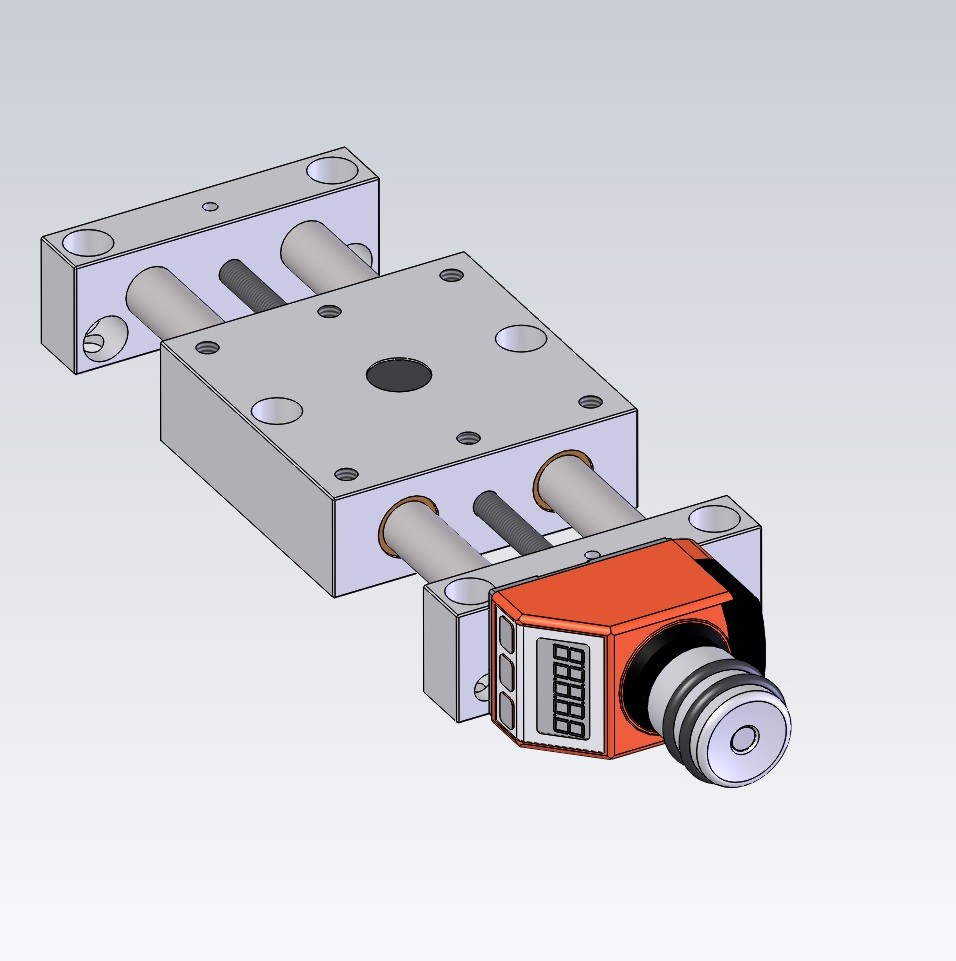

long positioning table with electronic position indicator PT7312-PAE

- from 5 for €516.80 each

- from 10 for €495.04 each

- from 25 for €478.72 each

- Spindle pitch 1mm

- Display accuracy 0.01mm

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| Katalog Positioniersysteme manuell / Catalogue Positioning Systems | 18.6 MB | Download | ||

| CAD (step) PT7312-PAE | zip | 426.4 KB | Download | |

| CAD (step) PT7312-PAE-2KH | zip | 548.4 KB | Download |

Function

- The slide of the positioning table can be adjusted linearly by hand by turning the control knob.

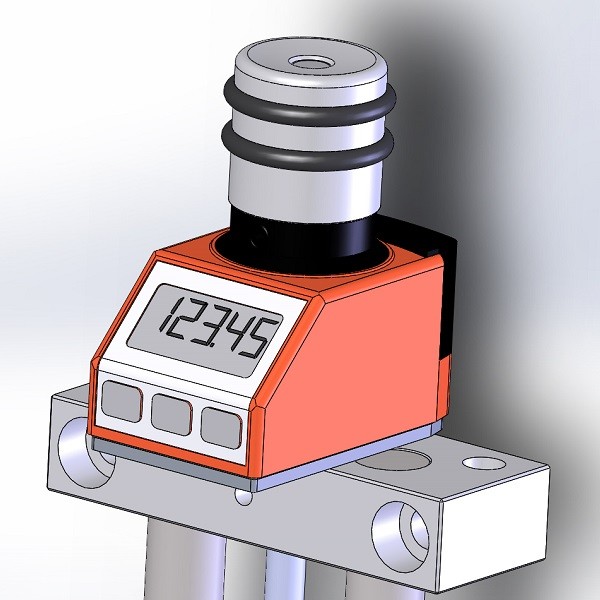

- The operator can read the slide position directly on the position indicator to an accuracy of 0.01 mm.

- The indicator can be reset to zero in any position by pressing a key.

- The position indicator is available in 2 designs and can be mounted in 4 positions.

- Due to the preloaded spindle and spindle nut, no clamping is necessary after adjustment.

- The spindle can be additionally fixed in the bearing block with the clamping screw KS-M4X7. (Accessories)

Advantages

No backlash

Spindle nut and spindle bearing are preloaded. This allows the slide to be positioned from either direction without backlash.

Self-locking spindle

Due to the preload, the control knob offers some resistance when turning. This means that the carriage always holds its position securely.

Modular system

The PT7312-PAE positioning stage can be easily extended with the other size 12 adjustment units to form a multi-axis system.

Special features

Functional position indicator

Reset, incremental measurement, offset via keyboard operation

Large LCD display

Battery life 2 years

Easy battery change without loss of settings

Variable mounting of the position indicator

The position indicator can be rotated 4 x 90° around the spindle axis and fixed. (Picture example "L" left)

Options

Numerical orientation for vertical position of the spindle

The position indicator is also available with 180° rotated (upside down) digits.

Spindle clamping

With the optionally available KS-M4X7 clamping screw, the spindle can be additionally clamped against rotation.

Hand crank instead of rotary knob

The handwheel, which can be ordered as an alternative, has a rotating crank handle and is used to adjust the spindle table more quickly.

Combination example

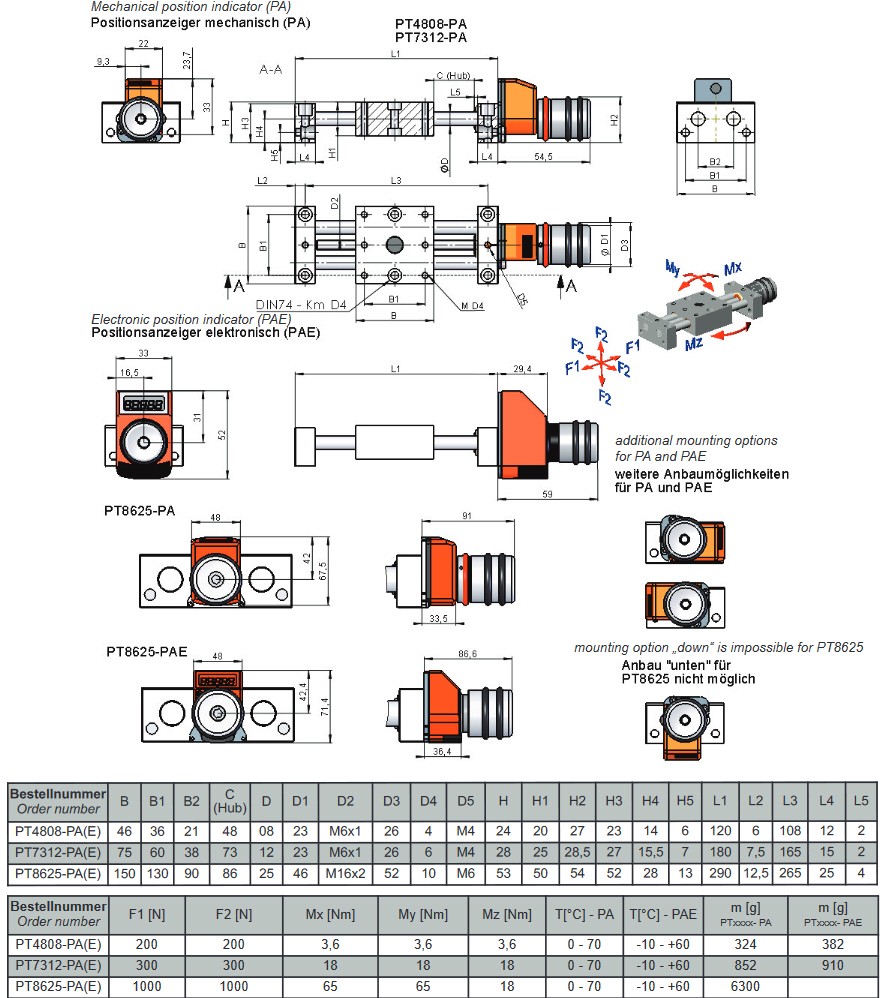

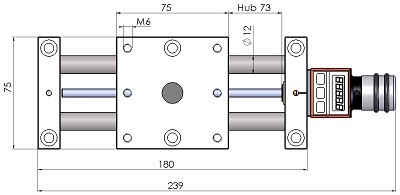

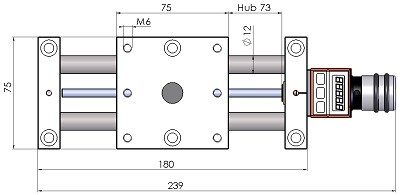

Dimensions

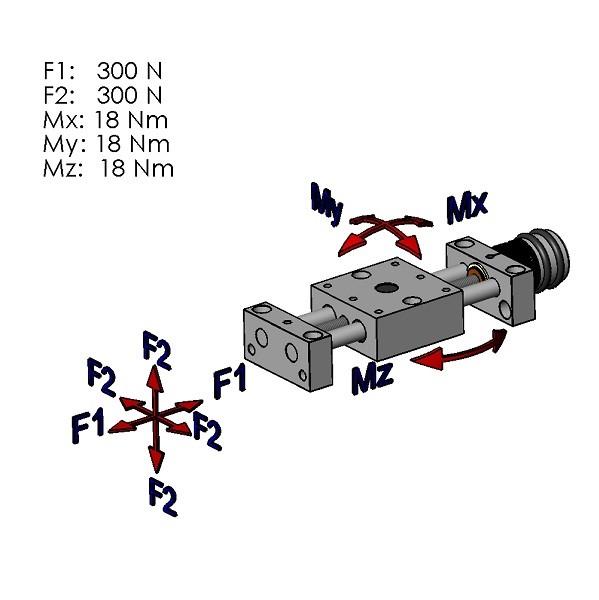

Force diagram

Technical data

Precision

Axial clearance: preloaded backlash-free

Radial play of the guide: <0.02 mm

Resolution of the position indicator: 0.01 mm

Dimensions and weight

Travel: 73 mm

Spindle pitch: 1 mm

Mass: 852 g

Operating temperature: -10 °C to +60 °C

Materials

RoHS compliant

Bearing blocks and slides: Anodized aluminum

Guide columns and spindle: stainless steel

Sliding bushes: brass

Position indicator: plastic

Dimensions

PT7312-PAE