FAQ Manual Positioning Systems

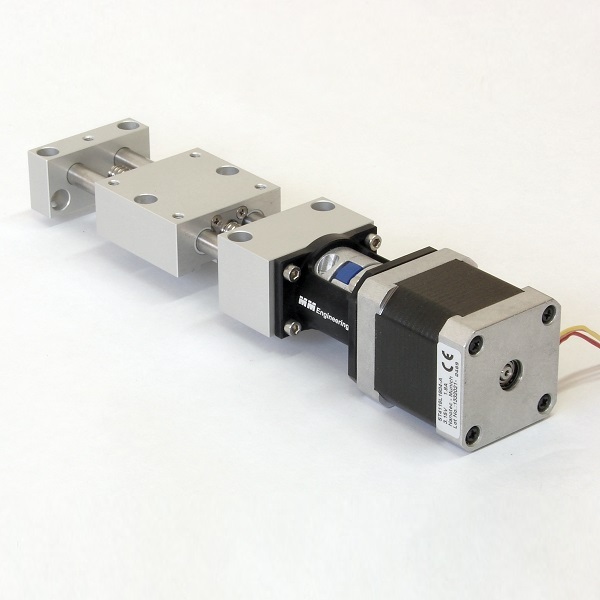

Motor attachment to a manually operated positioning axis

Can I add a motor to my positioning table?

We don't recommend it. Both the spindle bearing and the spindle nut are preloaded and therefore free of play and somewhat stiff.

Operation with a motor could overheat and damage the preloaded bearings. We have modular-compatible motor positioning tables for this purpose. These are suitable for continuous operation.

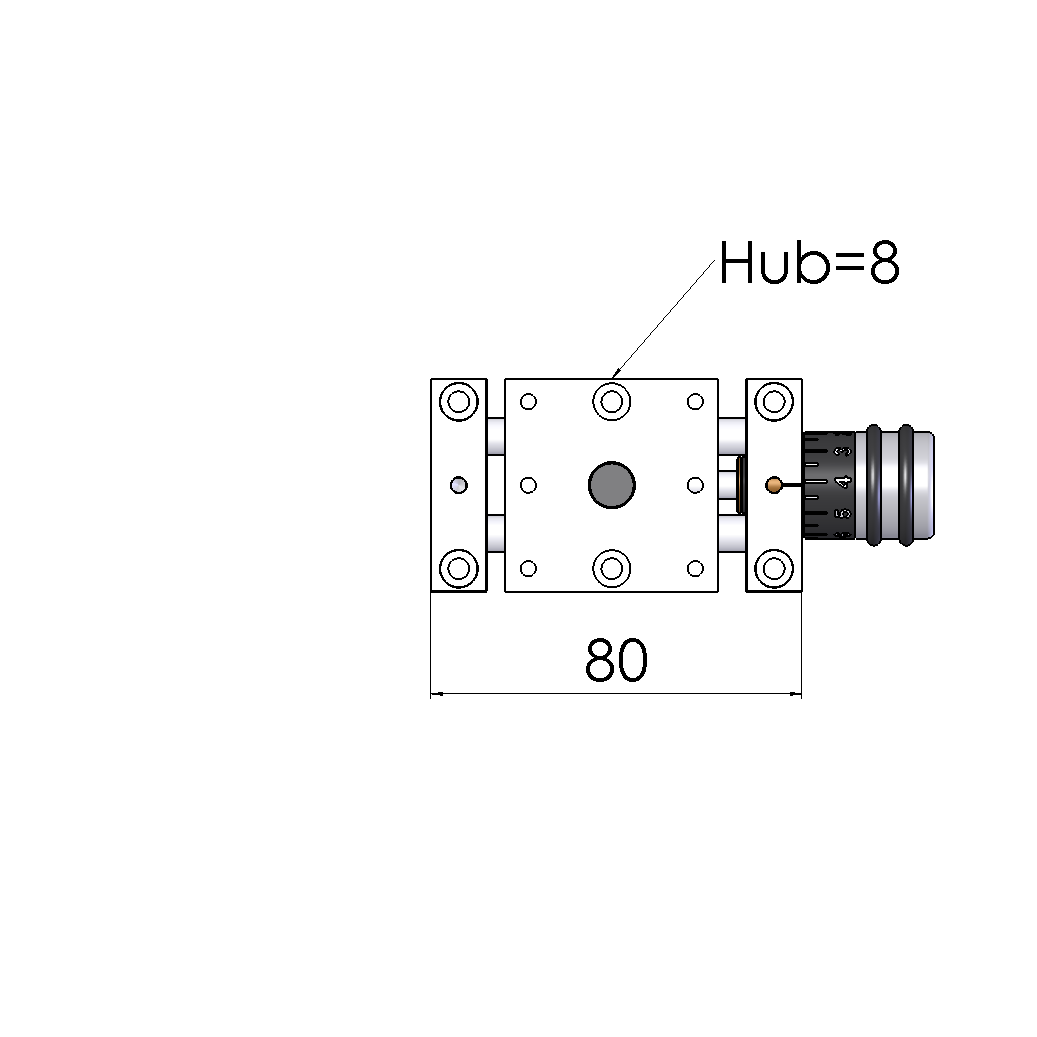

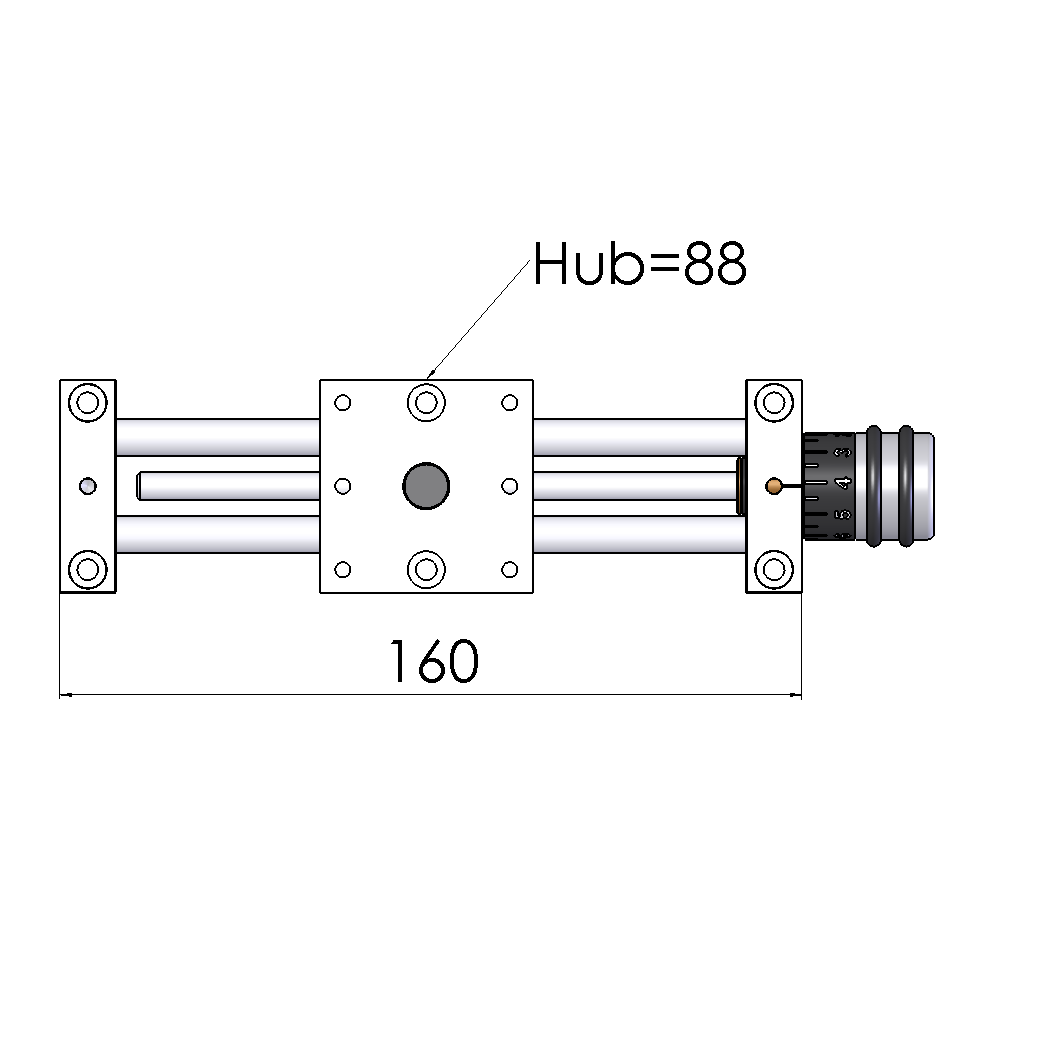

Manual linear axes in special lengths

Are the linear tables also available in other lengths?

Yes. We can manufacture the long positioning tables and long XY tables in any length (as far as this makes sense) for a small surcharge. Just ask about this. Please use our contact form for this.

Advantage of a shorter stroke: the unit becomes stiffer.

Disadvantage with a larger stroke: The unit becomes more unstable.

Clampable spindle tables

Can I clamp the positioning tables?

In general, it is not necessary to clamp the positioning tables and rotary tables, since the preloaded spindle and worm bearings are self-locking due to their sluggishness.

With the lifting and positioning tables, the spindle can be clamped using an additional clamping screw in the bearing block to prevent unintentional adjustment.

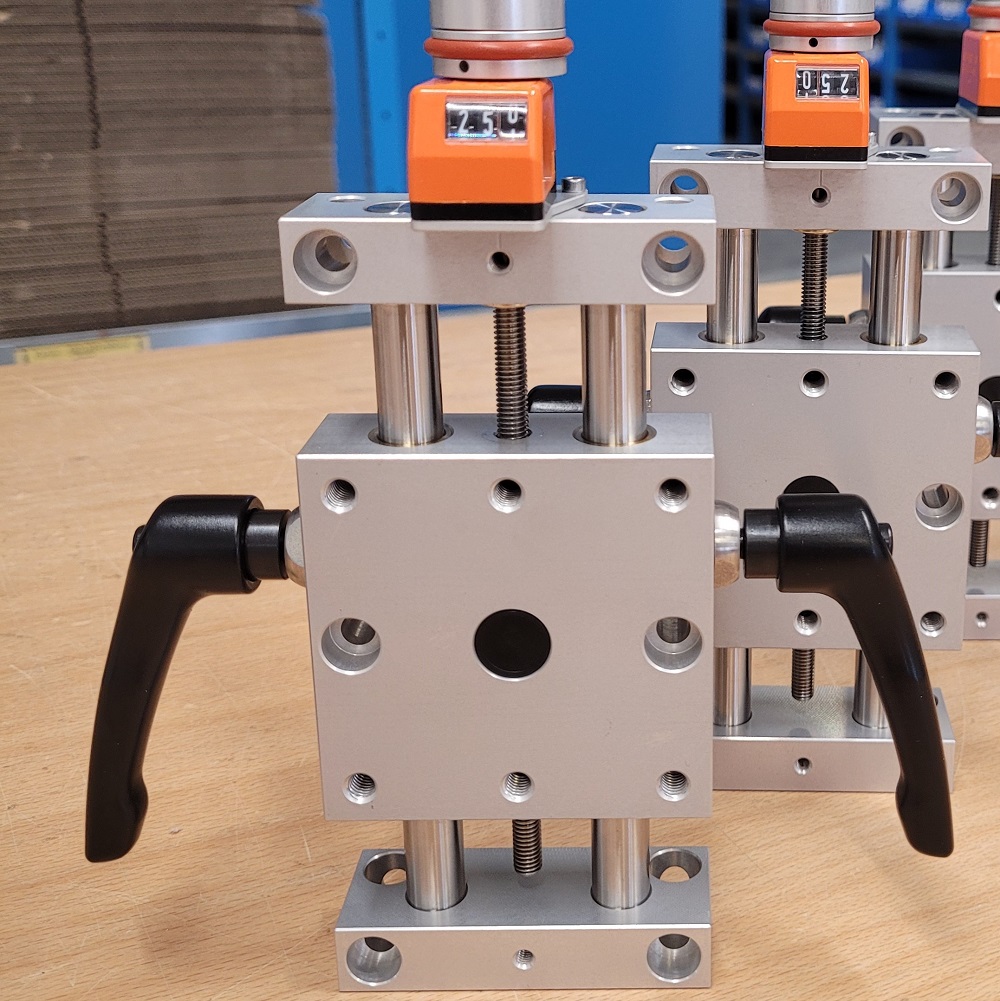

With the positioning tables, the carriage can optionally be clamped on the guide rods. There are 1 lever on the left and right of the table, with the help of which the table is clamped with the guides.

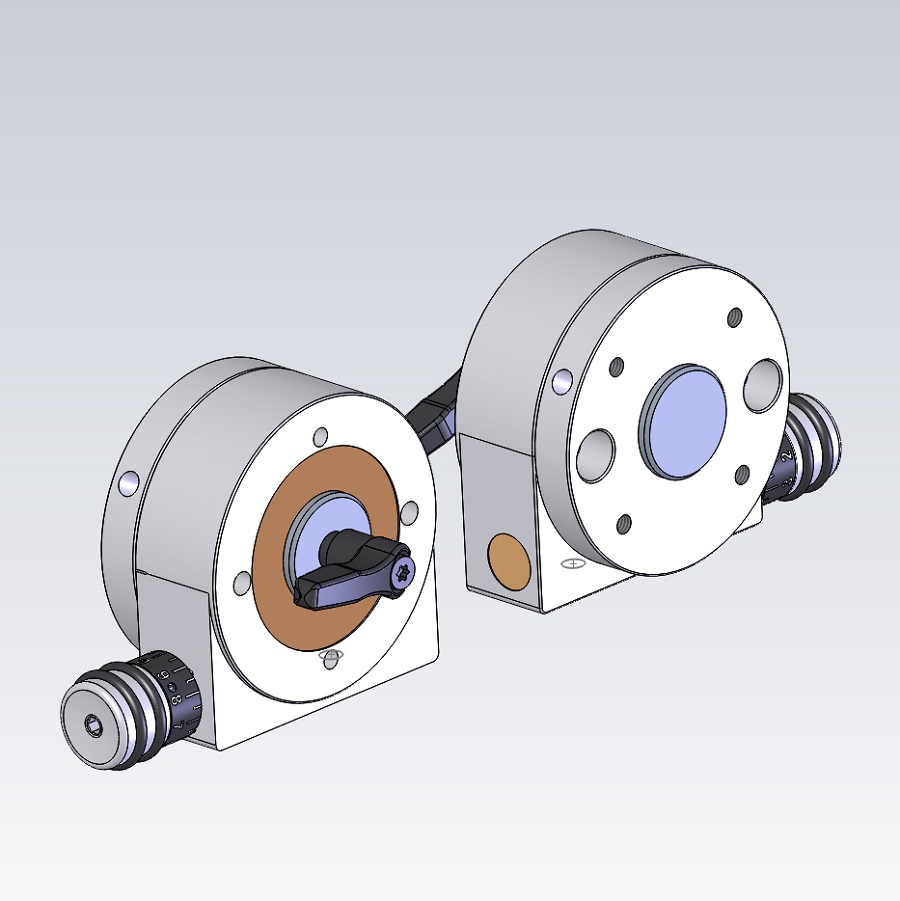

Locking the turntables

How do I fix the position of the turntable on the rotary tables?

Here, too, it is not necessary to clamp the turntable disc, since the pre-stressed worm has enough sluggishness against the worm wheel to hold the set position.

Nevertheless, we offer an additional clamping device to fix the set position for our turntables. Here, the turntable is clamped axially against the housing by means of a pull rod and a clamping lever.

Since clamping is coaxial here, the disc is not laterally loaded and pushed out of its position when clamped.

Maintenance of the adjustment units

Do the adjustment units have to be serviced?

No. The manually adjustable positioning units are maintenance-free. When dirty, we recommend regular cleaning.

Manual positioning axes with various controls

Are there any other controls besides the knob?

Yes. We also offer crank handles for the positioning units with position display that do not require a scale on the rotary knob. The hand crank enables quick adjustment.

The adjustability of the display independently of the spindle, e.g. to set the zero point, is completely retained.

Example: Short positioning table with position indicator and hand crank 63mm PT1408-PA-H-O-HK63 Simply click on the "Type of control element" option "Hand crank 63mm".