Handling Systems

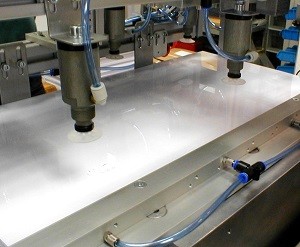

Suction Lifters in the sheet feeder separate plastic sheets

So-called lifting vacuums or also separating vacuums are used to cut stacked flat workpieces. In this example the properties of the MM Engineering vacuum suction lifters are required for a sheet feeder for plastic sheets. The partially statically charged, difficult-to-separate sheets are separated by blowing compressed air into the stack from the front.

The lifting cylinders extend and simultaneously suck in air.

As soon as the suction lips of the suction cups seal with the top arc, the direction of movement of the piston reverses and the workpiece is torn up. The direction is reversed so quickly that the air cushion between the arches is not compressed and the arches remain separate. This does not require an external control pulse for reversing the direction. The vacuum suction lifter does it by itself.

The use of the same line lengths ensures that several cylinders work synchronously. The sheet that has been separated and fixed in this way is then fed to the machine. The MM Engineering suction lifters are also available with a storage function and with integrated vacuum generation.

Vacuum suction lifters for separating of signs

A type label is written by a labeling laser, while the sign is lying fixed on a stack in the magazine. After labeling and releasing the clamp, the top plate is separated from the stack by a sharp blowing air pulse. Floating on the air cushion, it is lifted by an IHS3025 integral suction lifter.

The vacuum lifting cylinder is so sensitive that the lower plate does not adhere to the part to be lifted. Then it is transported via the removal magazine using a motorized linear unit.

After switching off the compressed air on the suction lifter, the piston rod extends automatically and the workpiece is released from the suction cup by the ejector pulse integrated in the suction lifter and is therefore safely stored in the magazine.

The complete cycle of the lifting cylinder (pick & place) is only controlled by switching the compressed air on and off.