Integral Suction Lifter IHS3025

Delivery Time

2-3 Tage

- from 5 for €394.33 each

- from 10 for €377.72 each

- from 25 for €365.27 each

Excl. 19% VAT,excl. Shipping Cost

- only one compressed air pipe necessary for creating vacuum and the lifting function

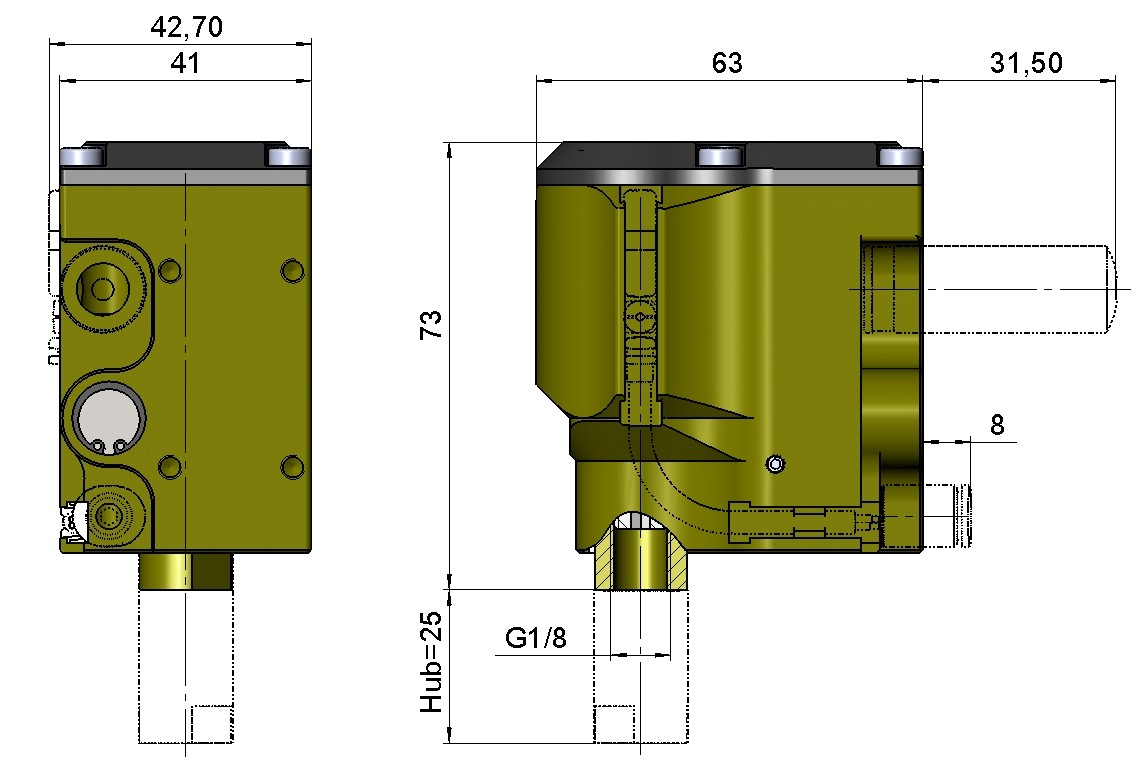

- travel = 25mm

- aperature of the piston= 30mm

- lifting power= 7N

- Piston rod twist-locked

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| CAD (step) IHS3025 | zip | 692.6 KB | Download | |

| Katalog Hubsauger / Catalogue Suction Lifters | 10.3 MB | Download |

Compressed air operated with place function

function:

- When the compressed air is switched on, an integrated ejector creates a vacuum

- The piston moves out

- As soon as the suction cup touches the workpiece it holds onto it and the piston immediately returns to its starting position with the workpiece

- As long as the compressed air is switched on the part remains locked in position

- When the compressed air is switched off, an integrated pressure chamber generates a blow-off pulse, causing the piston to move out again and put down the workpiece

- When the pressure chamber is empty, the spring resets and the piston retracts again

- The retracted piston position can be monitored by using a magnetic field sensor (see accessoirs)

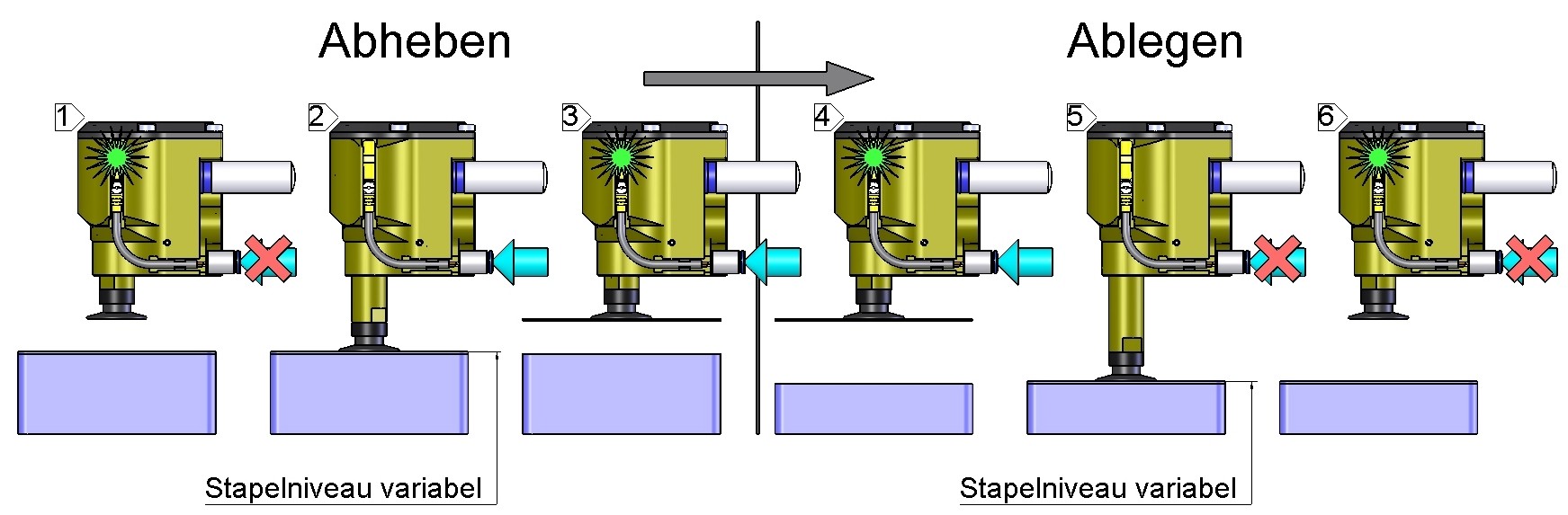

course of motions:

- basic position, compressed air switched off, pistion is retracted, magnetic field sensor is actuated

- compressed air switched on, piston moves out, workpiece is picked up, piston moves back with picked up workpiece into its starting position

- workpiece held and lifted, compressed air is switched on , magnetic field senor is actuated

- transfer with workpiece

- compressed air switched off, piston moves out with workpiece,puts down workpiece ad returns to starting position without workpiece

- basic position, compressed air is switched off, pistion is retracted, magnetic field sensor is actuated

advantages:

- the whole course of motions will only be operating with switching on/off the compressed air

- No additional valve or cylinder necessary

- short cycle times

- significant cost saving

- no compression of isolated parts

- low tare weight answerable for fast movement

- balance different heights of workpieces

- correct position withdrawel because of non rotating plunger

- the picked up workpiece will be put down automatically

- no problem with long vacuum pipes

- magnetic field sensor for monitoring the picked up workpiece - no uncertain monitoring of the vacuum by using a difficult vacuum switch

- compressed air is switched on + magnetic field sensor is actuated = workpiece will be picked up

use:

- lifting and putting down of workpieces by using "pick and place" function

- simultaneously picking up and lifting of plane workpieces

- seperating paper, plastic bows, inlay, labels, check cards and other plane workpieces

- irrespective of the piles' height

Write Your Own Review

We found other products you might like!