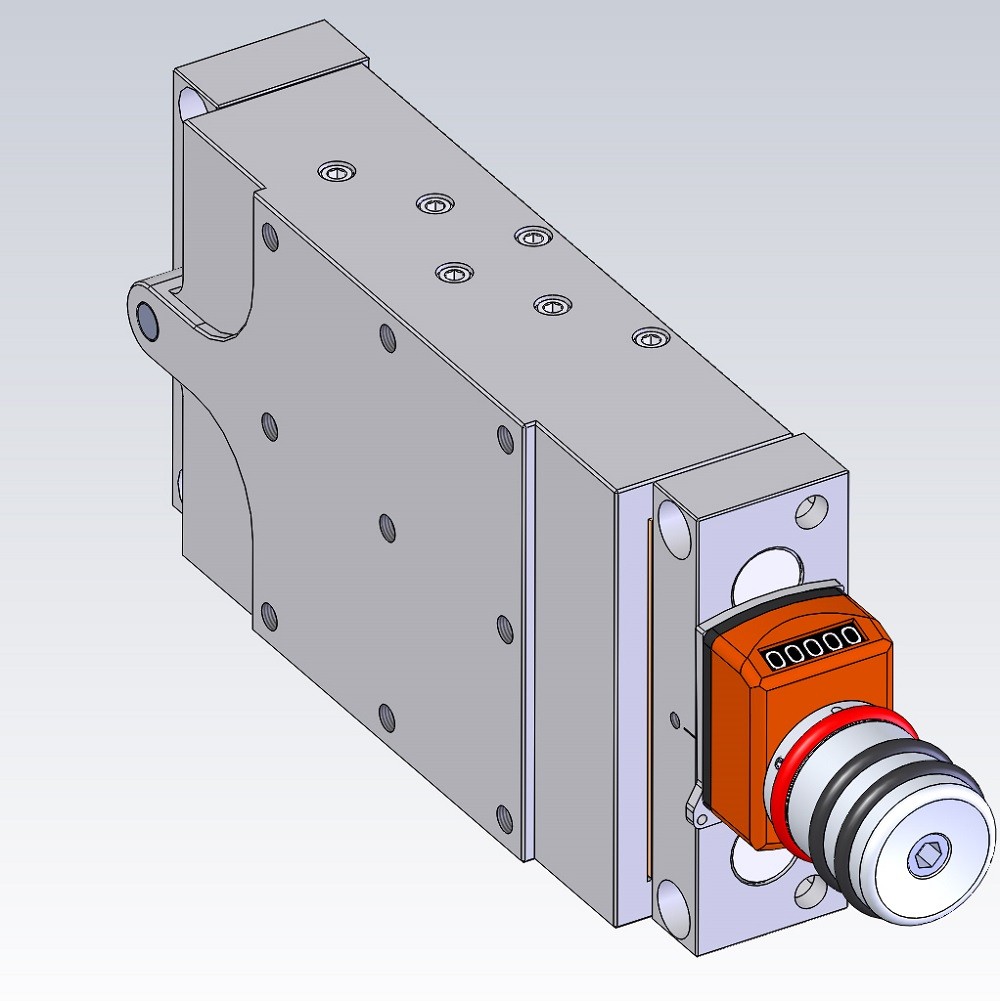

Vertical Lift Stage with mechanical Position Indicator HT25-PA

- from 5 for €1,084.20 each

- from 10 for €1,038.55 each

- from 25 for €1,004.31 each

- Lifting force 700 N

- Display accuracy 0.1 mm

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| Katalog Positioniersysteme manuell / Catalogue Positioning Systems | 18.6 MB | Download | ||

| CAD (step) HT25-PA | zip | 457.6 KB | Download |

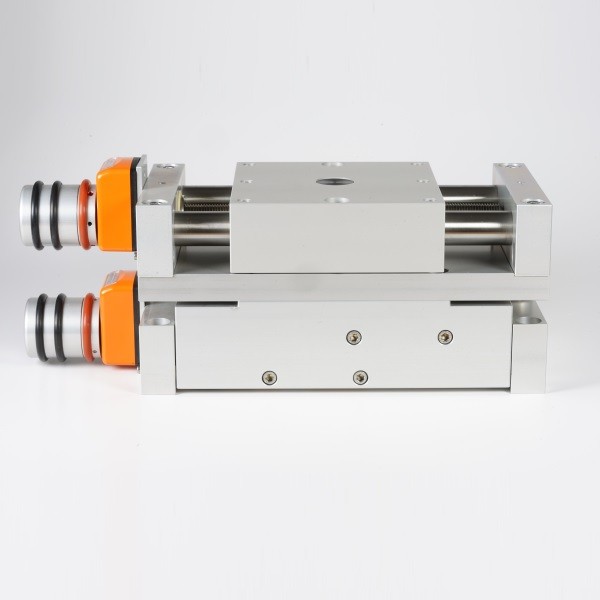

Function

- The height of the vertical lift stage plate can be adjusted manually by turning the scale knob.

- The adjustment travel is directly indicated by the position indicator in 0.1mm increments.

- Due to the preloaded spindle and spindle nut, no clamping is necessary after adjustment.

- The spindle can be additionally fixed in the bearing block with the clamping screw KS-M6x13 (accessory).

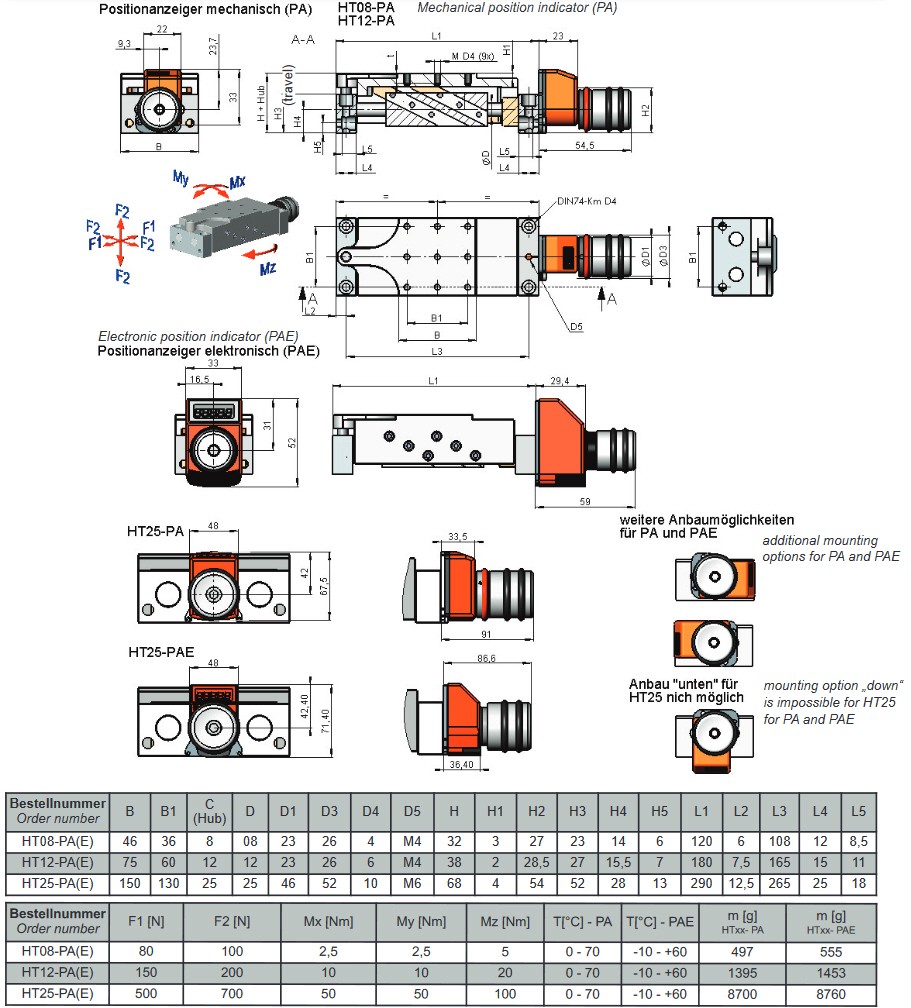

- Position indicator available in 2 designs and 3 mounting positions.

Advantages

Self-locking spindle

Due to the preload, the control knob offers some resistance when turned. In this way, the lift plate always holds its position securely.

Modular system

The vertical lift stage HT25-PA can be easily extended with the other size 25 adjustment units to form a multi-axis system.

Special features

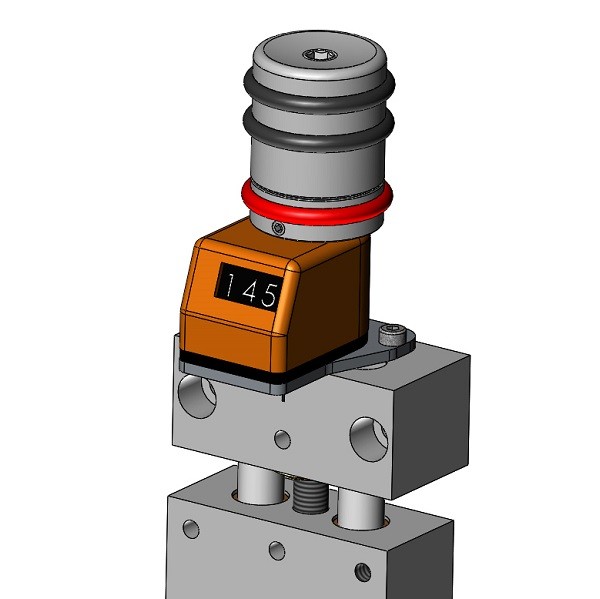

Variable mounting of the position indicator

The position indicator can be rotated 90° to the left or right around the spindle axis and fixed. (Picture example "R" Right)

Zero position freely selectable

On the red adjustment ring, the display value can be adjusted independently of the spindle after loosening the clamping screw.

Options

Numerical orientation for vertical position of the spindle

The position indicator is also available with 180° rotated (upside down) digits.

Spindle clamping

With the optionally available KS-M6x13 clamping screw, the spindle can be additionally clamped against rotation.

Kombinationsbeispiel

Positioniertisch lang mit mechanischem Positionsanzeiger PT8625-PA

Hubtisch mit mechanischem Positionsanzeiger HT25-PA

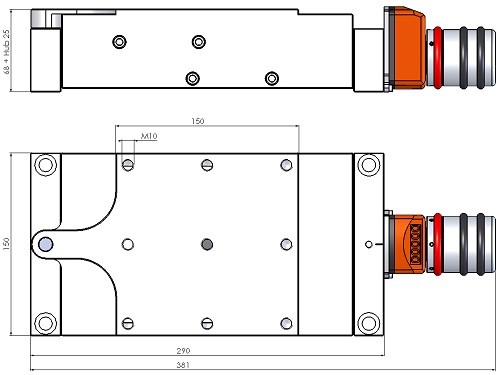

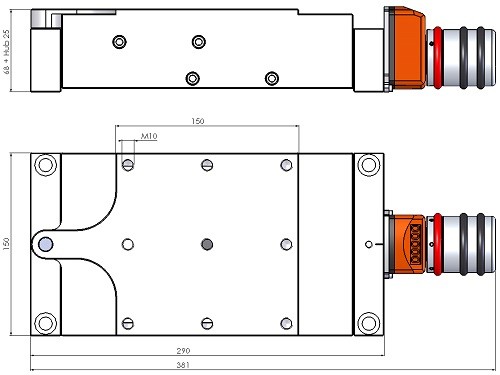

Dimensions

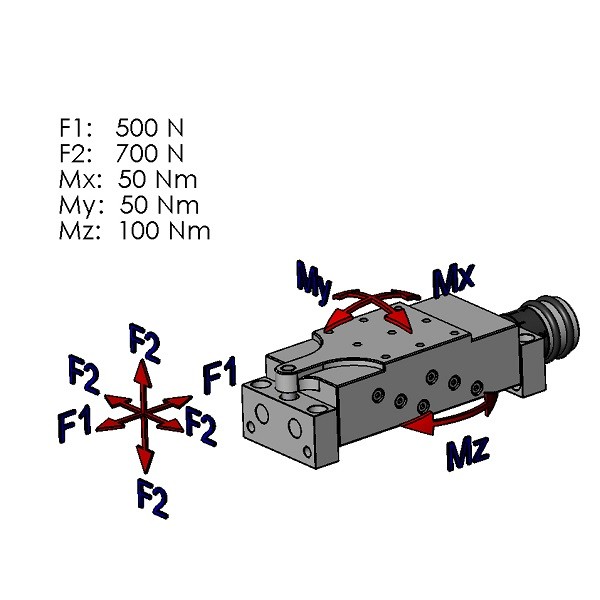

Force diagram

Technical data

Precision

Backlash: <0.05 mm

Lateral play of the guides: <0.02 mm

Resolution of the position indicator: 0.1 mm

Dimensions and weight

Travel: 25 mm

Mass: 8700 g

Operating temperature: 0 °C to 70 °C

Materials

RoHS compliant

Bearing blocks, slide and lifting plate: anodized aluminum

Guide columns and spindle: stainless steel

Sliding bushes and sliding rails: brass

Position indicator: plastic

Dimensions

HT25-PA

Order code

Industries and applications:

The spindle vertical lift stages from MM Engineering are specially developed for use in machine and special machine construction in many branches of industry, model making in the automotive industry and for precise solutions, e.g. in the optical industry. Countless add-on variants, such as linear tables, rotary and swivel elements enable the exact adjustment of the Z-axis with an accuracy of 0.1 mm for the PA version = mechanical position indicator. In the version with the electronic position indicator PAE, an accuracy of 0.01 mm is achieved.